Cutting in confined places and tat Gas

Gravity is

very important. Always be wary of equipment leaks.

[]

PROPANE FLAMMABLE LIMITS AIR 68oF 20oC. 1 atm 101.3kPa = 3.4-13.8%

[]

PROPANE FLAMMABLE LIMITS OXY 68oF 20oC. 1 atm 101.3kPa = 2.5-55%

[]

PROPANE FLAME VELOCITY AIR 1 atm. 101.3kPa = 1.48 ft/sec 0.45 m/sec

[]

PROPANE FLAME VELOCITY IN OXY 12.2 ft/sec 3.7 m/sec.

[]

PROPANE HEAVIER THAN AIR 60oF 15.6oC PROPANE = 1.5 AIR = 1

[]

PROPANE VAPORIZATION PRESSURE 70oF 21oC = 109.7 psi 756.6 kPa

[]

TOTAL HEAT AFTER VAPORIZATION 2498 Btu/CF 104 MJ/cum.

[]

PROPANE TOTAL HEAT AFTER VAPORIZATION 21800 Btu/lb 51000 KJ/kg

[]

PROPANE PLUS OXYGEN TEMPERATURE 4579oF 2526oC

[]

PROPANE PRIMARY FLAME HEAT 255 Btu/CF 10 MJ/cum

[]

PROPANE OUTER FLAME HEAT 2243 Btu/CF 94 MJ/cum

[]

COMPARE NG PRIMARY FLAME WITH OXYGEN 11 Btu / CF

0.4 MJ/cum

[]

COMPARE NG SECONDARY FLAME WITH OXYGEN 989 Btu

/ CF 37 MJ/cum

[]

COMPARE PROPYLENE. PRIMARY FLAME HEAT 433 Btu/CF

16 MJ/cum

[]

COMPARE PROPYLENE SECONDARY FLAME HEAT 1938 Btu/CF 72 MJ/cum

[]

COMPARE ACETYLENE. PRIMARY FLAME HEAT

507 Btu /CF

[] COMPARE ACETYLENE SECONDARY FLAME 963 Btu/CF

[]

PROPANE AUTO IGNITION TEMP AIR 1 atm 101.3kPa = 919oF 493oC

[]

PROPANE AUTO IGNITION TEMP OXY 1 atm 101.3kPa = 874oF 468oC

[]

PROPANE CRITICAL DENSITY 13.5 lb/CF 217 kg/cum

[]

PROPANE CRITICAL PRESSURE 616 psi 4246 kPa abs

[]

PROPANE CRITICAL TEMPERATURE 206.3oF 96.8oC

[]

PROPANE MILD ANESTHETIC CAN CAUSE SUFFOCATION 50% IN AIR

[]

PROPANE LIQUID CAN CAUSE FREEZE BURNS

[]

DON'T STORE PROPANE & OXIDIZING GASES TOGETHER - LEAKS SEEK LOW LEVELS

[]

USE CO2 POWDER EXTINGUISHERS ON FLAME - STORE IN NO FLAME AREA

[]

PROPANE IS NON CORROSIVE CAN BE USED WITH MOST METALS.

PROPYLENE

PROPYLENE

(C3H6) LP GAS BY PRODUCT OF OIL REFINING. THIS FUEL GAS HAS PROPERTIES IN WHICH

A GOOD INNER AND OUTER FLAME HEAT IS GENERATED. SUPERIOR TO PROPANE AND NAT GAS.

AND SAFER THAN ACETYLENE. YOU WILL USE MORE OXYGEN WITH THIS GAS THAN ACETYLENE

DOES.

[]

PROPYLENE NON TOXIC WITH MILD ANESTHETIC EFFECT

[]

DON'T STORE PROPYLENE WITH OXIDIZING GASES

[]

AVOID OZONES CHLORINE GAS FLUORINE HYD CHLORIDE

[] AVOID NITROGEN PEROXIDE

NEAR PROPYLENE

[]

PROPYLENE IN AIR ABOVE 50% VOLUME SUFFOCATION MAY OCCUR

[]

PROPYLENE LIQUID CAN CAUSE FREEZE BURNS

[]

PROPYLENE IN OXY FLAME TEMPERATURE 5193oF 2867oC

[]

PROPYLENE PRIMARY FLAME HEAT 433 Btu/CF 16 MJ/cum

[]

PROPYLENE SECONDARY FLAME HEAT 1938 Btu/CF 72 MJ/cum

[]

COMPARE NG PRIMARY FLAME WITH OXYGEN 11 Btu / CF

0.4 MJ/cum

[]

COMPARE NG SECONDARY FLAME WITH OXYGEN 989 Btu

/ CF 37 MJ/cum

[] COMPARE PROPANE. PRIMARY FLAME HEAT 255 Btu/CF

10 MJ/cum

[]

COMPARE PROPANE OUTER FLAME HEAT 2243 Btu/CF 94 MJ/cum

[]

COMPARE ACETYLENE. PRIMARY FLAME HEAT

507 Btu /CF

[] COMPARE ACETYLENE SECONDARY FLAME 963 Btu/CF.

[]

PROPYLENE FLAME VELOCITY IN OXY 15 ft/sec

[]

HEAT VALUE AFTER VAPORIZATION 2371 Btu/CF 88 MJ/cum

[]

HEAT VALUE AFTER VAPORIZATION 21000 Btu/lb 49000 KJ/kg

[]

PROPYLENE AUTO IGNITION TEMP AIR 1 atm 101.3kPa 851oF 455oC

[]

PROPYLENE CRITICAL DENSITY 14.5 lb/CF 232 kg/cum

[]

PROPYLENE CRITICAL PRESSURE 670.3 psi 4620 kPa

[]

PROPYLENE CRITICAL TEMPERATURE 197.5oF 91.9oC

[]

PROPYLENE FLAMMABLE LIMITS AIR 68oF 20oC 1 atm = 2-11%

[]

PROPYLENE FLAMMABLE LIMITS OXY 68oF 20oC 1 atm = 2-53%

[]

PROPYLENE HEAVIER THAN AIR AIR=1 PROPYLENE = 1.48

[]

PROPYLENE = 4.35 lb/GAL 1-lb = 9.7 CF 0.27 cu m

[]

PROPYLENE VAPORIZATION PRESSURE 70oF 21oC = 132.8 psi 915.7 kPa

[]

MAXIMUM PROPYLENE REGULATOR PRESSURE IS CYLINDER PRESSURE.

MAPP GAS

IF

I REMEMBER CORRETLY, THIS FUEL GAS CAME ABOUT BECAUSE DOW CHEMICAL WANTED A SALES

SOURCE FOR SOME OF ITS BY PRODUCTS.

IF

I REMEMBER CORRETLY, THIS FUEL GAS CAME ABOUT BECAUSE DOW CHEMICAL WANTED A SALES

SOURCE FOR SOME OF ITS BY PRODUCTS.

THE

BOTTOM LINE. I DON'T BELIEVE THE WELD INDUSTRY NEEDS THIS FUEL GAS MIX. MAPP WORKS,

BUT IT'S COMPOSITION COMPLEXITY AT THE END OF THE DAY, PROVIDES FEW IF ANY BENEFITS IN

CONTRAST THE MUCH LOWER COST PROPANE.

TALKING

ABOUT SALEMANSHIP, YOU MAY HAVE HEARD OF A FUEL GAS CALLED FLAMEX. HOW SHOULD

I DESCRIBE FLAMEX. TAKE A GALLON OF PROPANE AND MIX IN AN OUNCE OF MUSTARD AND

GIVE IT A UNIQUE NAME THAT ENDS WITH AN X. THEN YOU TELL A GULLABLE INDUSTRY YOUR

FUEL GAS HAS UNIQUE CUTTING CAPABILITY AND WELD SHOPS SNAP IT UP. WELL THAT SURELY

COULD NOT HAPPEN IN THE USA AND CANADA NOW COULD IT?

[]

MAPP C3H4 METHYLACETYLENE PROPADIENE

[]

MAPP IS STABILIZED WITH PROPANE ISOBUTANE ISOBUTYLENE

[]

MAPP 1-lb = 9.06 CF 0.25 cu/ m 1kg = 19.9 CF 0.56 cu m

[]

MAPP MOLECULAR WEIGHT 42.3 VAP. HEAT 227 Btu/lb 0.53 MJ/kg

[]

MAPP TOTAL HEAT OF COMBUSTION 21700 Btu/lb 50.5 MJ/kg

[]

MAPP BOILING RANGE 1 atm 101.3kPa = -36 -4oF / -38 -20oC

[]

MAPP FLAME TEMPERATURE IN OXY 5301oF 2927oC.

[]

MAPP FLAME VELOCITY 15.4 ft/sec 4.69 m/sec

[] MAPP AUTO IGNITION TEMPERATURE

IN AIR 851oF 455oC

[]

MAPP FLAMMABLE LIMITS IN OXY 2.5-60%

[]

MAPP FLAMMABLE LIMITS IN AIR 2.5-11%

[]

MAPP VAPORIZATION PRESSURE 70oF 21oC = 94 psi 645 kPa

[]

MAPP SPECIFIC GRAVITY GAS 60oF 15.5oC = 1.48 AIR=1

[]

STORAGE EQUIPMENT FOR MAPP SAME AS PROPANE

[]

MAPP SERVICE LINES IRON - STEEL ALLOY -

[]

DON'T USE Cu CONTAINING MORE THAN 60% Cu

[]

REGULATORS TORCH MANIFOLDS VAPORIZERS - USE MAPP APPROVED

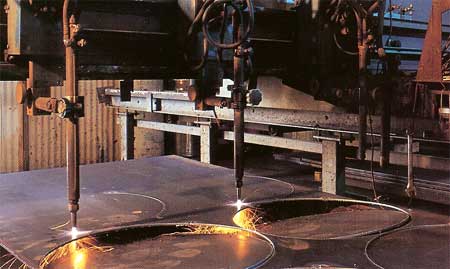

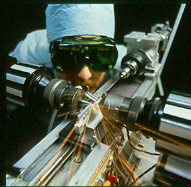

Note

on Laser and Oxy Fuel Cut Edges and Scale:

Laser

cut surfaces with oxygen assist gas can influence weld quality.

Laser

cut surfaces with oxygen assist gas can influence weld quality.

When

oxygen is used as the laser assist cutting gas, the oxygen causes the formation

iron oxides. The laser oxy assist gas accelerates the formation of oxidation,

similar to oxy - fuel cutting. The laser cut surface scale is similar to rust.

Typically the laser cut surface is made up of black magnetite (ferrous

oxides). Keep in mind also that carbon can migrate to the laser cut edge. This

carbon can increase the carbon content of the future welds. When nitrogen is used

as the assist gas, the amount of oxidation is minimal. Oxy assist gas laser cutting

provides faster cutting speeds than nitrogen on carbon steels. Nitrogen is used

for stainless.

The laser scale is brittle it can be

detrimental to the weld and is also a poor surface for paint or coatings.

If you are interested in improving your career and becoming a weld professional with MIG and flux cored weld process control and best weld practice expertise, click here.

Weld reality Home Page.