|

|

Welcome to the world's largest web site on MIG , Flux Cored and TIG. Weld Process Controls & Best Weld Practices. To get to the root cause of GMAW (MIG) & Flux Cored (FCAW) weld issues, requires Weld Process Control - Best Practice Expertise, & lots of Weld Reality. The site provides the MIG - Flux Cored and TIG weld information and data required to attain the highest possible manual and robot weld quality, always at the lowest possible weld costs.

This web site was first established in 1997 by Ed Now Em Craig. Contact Ed. ecraig@weldreality.com

Weld Isues on Cars and Trucks.

I placed the above text in this picture in 2000

and 18 years later read the next paragraph.

Section 1.

2015: CHRYSLER: IMPORTANT AXLE SAFETY RECALL N26 / NHTSA 13V-239

This notice applies to vehicles (VIN: xxxxxxxxxxxxxxxxx). This notice is sent in accordance with the requirements of the National Traffic and Motor Vehicle Safety Act. Chrysler has decided that a defect, which relates to motor vehicle safety, exists in some 2012 model year RAM Truck Cab Chassis (4500/5500 series) trucks equipped with four wheel drive.

The problem is the front axle tube welds on the trucks may not have been welded correctly during the manufacturing process. Improperly welded front axle tubes could allow the differential housing to rotate under high torque operating conditions while in four wheel drive. Should the front axle tube welds break, the differential could rotate and cause the front propeller shaft universal joint to break. This can result in a loss of motive power or damage to surrounding components if the propeller shaft continues to spin after separation. This could cause a crash without warning.

Axle weld issues are common in the auto - truck industy and the weld reality is with either robots or manual welds, these are the easiest applications to weld on any vehicle..

A look at Auto / Truck Industry, Manufacturing Management,

and Product Recalls and Accountability.

The greatest opportunity for dramatic weld productivity / quality improvements, and also for weld cost reductions, is typically found in large weld shops and ship yards and especially in just about every global plant that provides robot MIG welds on car and truck parts.

Welding and Mfg. Management:

As above those robot welds that daily require

extensive weld rework, are an INDICATION OF WHAT?

GLOBAL MANUFACTURING, MANAGEMENT AND ENGINEERS:

The latest ISO, Six Sigma and Lean Manufacturing practices and standards have been successfully implemented. The company has never had more Black Belts wrapped around over sized waists while walking the factory floors, yet from a manufacturing perspective it did not matter which direction you looked, the evidence of lack of manufacturing process controls was overwhelming and the weld rework bins are always over flowing.

I wrote the following in 2005: For the first time in this corporation's history, this companies global auto / truck recall costs in 2005 surpassed two billion dollars.Sounds unreal, take your pick, Chrysler, Ford, GM and many tier one companies easily meet this criteria.. Now come forward to 2018 and the annual recalls, rejects and rework costs from these and other global auto companies will typically far surpass the companies profits

In production plant "B" in the old Detroit facility, the daily robot weld production efficiency was typically less than 60%, the down time was excessive and the manual weld rework required was in the 40 to 70% range. THE ENGINEERS AND MANAGEMENT SOLUTION, " PURCHASE MORE ROBOTS" ....

The customers manufacturing & quality ignorance,

provides relief for many of the auto / truck manufacturers:

If auto / truck customers truly understood the requirements for weld integrity and the role vehicle designers intend their welds to play both in the vehicle life and more importantly when a vehicle is in a collision, we would have more people crawling under that car or truck before they put their money down.

In manufacturing and "welding" steel components for cars and trucks, their is little evidence from North American, Japanese or European manufacturers of the establishment of effective

"Robot Weld Process Controls" and absolutely no sign of any multi-plant, international corporations establishing "Global Robot Weld Best Practices".

I have been in numerous auto / truck facilities in ten different countries and rarely found a manufacturing manager that understood the real robot weld production efficiency from his robots and more importantly how to control weld cost / quality and keep the daily robot weld rework to less than 2%.

2004. Robot frame welds on the world's best selling trucks:

WELDS AND PRODUCT LIABILITY:

Many of the poor welds witnessed for decades in auto / truck plants, along with the overwhelming evidence of corporate / manufacturing management process control apathy will one day provide the ammunition lawyers require. It will not take rocket science to prove that a critical structural component failure of a car / truck in a crash, was partially a result of MIG welds on the vehicle that lacked weld integrity. Lawyers will readily find evidence of poor quality welds due to "manufacturing management / engineering negligence".

Each day thousands die in vehicle collisions, yet how many may have lived if the vehicle welds

and structure were built in the manner the designer and manufacturing instructions required?

Defective Welds and Recall Terminology.

1998: You will rarely see a car or truck recall for "defective welds", as they would have to replace almost every global vehicle and the costs and liability amifications could be extensive .

Lets face it, an auto or truck manufacturer will take great care in it's "product failure descriptions to avoid the words "weld failure". For example if a company discloses that the truck or car frame has a structural defect issue, it's typically an indication of a major manufacturing process control break down and therefore that break down will typically cover more than a single small defect. Also most high steel parts subject to weld repairs will be carried out at body shops who are not qualified to carry out the repairs so that the repaired product is now in compliance with the orgional design criteria with the mechanical properties specified.

A repeating major weld defect on high volume welded parts would point to the inability of manufacturing management and engineers to regulate and optimize a simple, two control, 50 year old manufacturing process, a process that could I could teach an 11 year old to learn and control in a few hours.

It's only an ASME pipe MIG weld..

Ed teaching Jesse 11 years old, in a few hours how to MIG weld a pipe.

Robot - Manual weld failures initiate from "Bad Weld Practices" and

a management's apathy - ignorance on "Weld Process Controls"

When weld issues are discovered on a vehicle, you are likely to see the weld issue recall notice announce something like this;

[] this recall is due to a "design suspension, axle or body ISSUE"

[] this recall is due an "integrity issue in the suspension",

[] this recall is due to a "component issue near the rear axle",

[] this recall is due to a "defective, door, latch, lug, bracket, bolt nut etc.".

It was a brand new $26,000 LEMON

MOST AUTO / TRUCK CUSTOMERS WILL NOT KNOW THEY HAVE A WELD OR VEHICLE WELD FABRICATION STRUCTURAL PROBLEM, THAT IS, TILL THEY END UP IN HOSPITAL OR FACE UP IN A COFFIN. Ed Craig. DEC 2005:

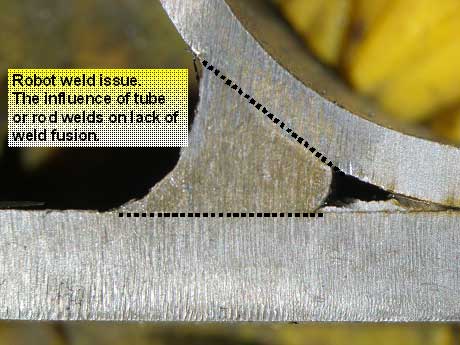

Note: The complete lack of weld fusion and the poor visual weld appearence that would have told anyone with a brain in the front office, that this weld was destined to fail.

From steels to aluminum welds, in the majority of auto / truck plants, you will find weld quality issues.

This robot truck weld macro indicates it has 200% more weld than it required, yet the weld joint is greatly weakened by the excess undercut. And another fact that impacts the costs, the robot required 70 % more time than it should have to make the welds, Small points lost on this Tier One company management and engineers.

2006. APPROX. 10 BILLION DOLLARS WAS SPENT THIS YEAR IN THE

AUTO / TRUCK INDUSTRY ON PRODUCT RECALLS AND WARRANTY ISSUES. JOE, YOU TELL ME. ARE WE BLOODY WELL MANUFACTURING TO CREATE PROFITS OR MANUFACTURING TO PAY FOR THE COSTS OF REWORK, REJECTS AND RECALLS?

In a world where too many managers and engineers have shied away from weld manufacturing equipment and process ownership, this web site as it has for the last 15 years, remains dedicated to the required manufacturing management and engineer

"Accountability - Responsibility and Ownership"

2007: As many auto part suppliers slowly sink towards chapter 11 or simply dissapear, and the global auto - truck mfg. executives bathe in their own design / manufacturing mediocrity, many of the corporate executives in this industry will sit back in their Ivory Towers, and place the responsibility for their poor mfg quality / productivity performance and the resulting annual profit quagmire on the trade unions and their wage demands, on the medical costs, on the pension costs, and with the ever changing so called third world labor costs. How often will you hear these same executives discuss the billions their companies have been loosing annualy for decades, costs on rejects, rework, recalls and warranty issues?

Manufacturing Managers, have you visited the

robot process control management section?

WANT TO KNOW WHAT SOME FORD EXECUTIVES THINK THEIR CUSTOMERS ARE WORTH?

2000. The US Senate , after a "rolling block" passed a watered down version of a consumer protection bill addressing the issues of tires and auto manufacturers withholding safety information from the government and the public. Apparently, a few of the more cretinish senators didn't want to impose criminal penalties on corporate CEOs who, with intent, withheld public safety information. This is the result of your auto manufacturer's lobby and money at work -- for them, not for you. Shouldn't every tire and auto manufacturer be able to make unsafe or defective products with impunity? Apparently, your government believes so. It may have been Ford that calculated the value of a human life to be approximately $200,000 when it decided not to replace or re-engineer a potentially defective part, because it would have cost the company more money to do. For more, visit, ttp://www.autobuyology.org/car6.html

Remember this web site is not about the latest car or truck recalls, I would have to hire a team just to keep up with that demand. The random recall information provided here barely touches the surface of the real recall issues.

The recall data presented here is simply to show the reader the scope of the issues and to emphasize that global manufacturing management chaos and mediocrity is today the norm and few auto / truck executives appear accountable for their manufacturing end results.

As the total annual recall / warranty costs typically exceed 10 billions, it's logical to assume that global auto manufacturers would rather not conduct recalls or pay for unnecessary warranty work, and lets face it, manufacturing defects do little for a companies reputation and future sales.The sad reality however for the car / truck purchaser, is only a micro amount of a car's or trucks problems will be identified by the majority of the vehicle manufacturers. It's ironic in 2005 that Toyota reported more vehicle recall problems than Chrysler, the question that consumers could ask is did Chrysler report all the vehicle problems it was aware of?

It's a sad statement that once your warranty is up, too often you are on your own, even though the vehicle manufacture may have been aware that the defects you report thirty days after the warranty has expired were there the day the vehicle left the plant. It's also a reality in 2005 or 2015 that many of the major global auto manufacturers are experts in defect denial, defect cover ups and keeping major problems isolated from the public in a cocoon of secret warranties and technical service bulletins.

2006 OR COULD BE 2016: THE PRICE OF MFG APATHY - MEDIOCRITY:

At this time in the history of vehicle manufacturing recalls mediocrity and the never ending costly warranty work required, the associated quality costs are pushing many of the major auto / truck companies and their suppliers towards eventual bankruptcy.

ONE OF THE MANY GREAT VEHICLE COVER UPS.

Mitsubishi recalls over a million of its vehicles self-admittedly stating they are poorly built vehicles. Mitsubishi also reportedly acknowledges that it hid consumer safety complaints for the past ten years.

Mitsubishi Motors and Mitsubishi Fuso Truck and Bus had recalls, that combined to 2,869,366 vehicles, or 38 percent of the tally for the entire country. Last year, Mitsubishi Motors disclosed that it failed to come clean five years ago and had more hidden defects. Both companies have seen sales plunge in recent years over the scandal.

Kude said a recent cover-up of auto defects at Mitsubishi Motors Corp. and its truck making affiliate Mitsubishi Fuso Truck and Bus Corp have had led motorists to be more vigilant about notifying authorities of possible defects or safety concerns.

Note from Ed: Many people are in prison today for smoking a joint, and these guys like the greedy bankers and crooked on the take politicians will likely end up with a slap on the wrist or by paying a fine.

ABC News: ORLANDO, Fla. Oct. 12, 2005 — AAA and the National Fire Protection Association will issue a warning tomorrow about car fires. ABC News has learned that last year, 266,000 car fires resulted in 520 deaths, the organizations say. "It was a horrible explosion," said one car fire victim Bob Aymar, who, in less than a minute, suffered third degree burns on his face, hands and arm. He was sprayed by a gasoline fireball during a violent traffic accident on a Southern California freeway. "The Bronco behind me was hit and it ruptured the gas tank," said Aymar, who, after seven surgeries, was finally able to play the piano again. He is just one of more than 1,300 car fire victims every year. According to the NFPA, cars catch fire on American highways once every two minutes. "The risk of a car or vehicle fire is even greater than the risk of an apartment fire. More people die in vehicle fires than in apartment fires each year in the United States," said AAA President Robert Darblenet.

266,000 CAR - TRUCK FIRES IN USA. 520 DEATHS & 1300 FIRE VICTIMS.

I CALL THIS THE "MANAGEMENT MFG. WEAPONS OF MASS DESTRUCTION"

The fires are again simply reflection of design and manufacturing engineering

issues found in so many vehicles....Is anyone going to take responsibility?

Are these "Management Issues?"

AFTER BUILDING THEM FOR 100 YEARS, YOU THINK THAT QUALITY WOULD MEAN MORE THAN A WORD IN A LOGO.

Warning for those that have just purchased that new car or truck and are unfortunate to end up in a vehicle crash, please remember as the sound of screeching tires and tearing metal invades your body and your senses;

[] the faulty tires may tear apart,

[] the seat belt brackets may not hold,

[] the steering wheel may fall off,

[] the seat welds may collapse,

[] frame and body welds will tear apart when they should have held,

[] the air bags may get stuck,

[] the axles welds may fail and the axles will collapse,

[] the wheels may drop off,

and if you survive the crash, the poorly designed and poorly built gas tank will start to

leak and premature cremation is a good possibility.

When you see the fireman in the following recalls you know why when you buy a new car or truck your first accessory should be a fire extinguisher.

Ford Manufacturing Management Issues:

Ford recalling 1.2 million trucks and vans recall is in addition to 4.6 million recalled last year for potential fire hazard.

August 4 2006: 10:45 AM EDT

NEW YORK (CNNMoney.com) -- Ford Motor Co. is recalling 1.2 million large pick-up trucks, SUVs and vans because of a problem with the vehicles' cruise control system that could lead to a fire. This recall is in addition to a total of 4.6 million Ford vehicles that were recalled for the same problem last year.The vehicles being recalled are: certain model year 1994 to 2002 F-250 through F-550 Super Duty trucks; 2000-2002 Excursion SUVs; 1994 to 1996 Econoline vans; 1996 to 2002 E-450 vans and 1998 Ford Explorer and Mercury Mountaineer SUVs. Diesel-powered vehicles are not affected.

In rare cases, the company said in a letter to the National Highway Traffic Safety Administration, brake fluid can leak through the cruise control deactivation switch causing corrosion in the switch. This can cause the switch to overheat and possibly burn. The switch shuts off the cruise control when the driver firmly steps on the brakes. The switch is located under the hood of the vehicle and is attached to the brake master cylinder on one end and wired to the cruise control on the other. On most of its models, Ford designed the switch to be powered -- or "hot" -- at all times, even when the vehicle is off. Inside the switch, a thin film barrier separates brake fluid from the switch's electrical components.

In January, 2005, Ford recalled approximately 800,000 F-150 pick-ups for the problem. Later that year, after numerous Ford owners complained that their vehicles caught fire when their engines were off and the keys weren't in the ignition, CNN launched an investigation into fires in Ford vehicles that had not been recalled .

In September, 2005, Ford recalled certain Bronco, Expedition, Lincoln Blackwood and Lincoln Navigator SUVs as well well as some Ford Ford F-150 and F-250 pick-ups for the same problem. A total of 3.8 million vehicles were recalled at that time. Ford stopped using the switch in 2002.

Associated Press:

WASHINGTON:

TRUCKS:2005: Ford and Toyota, two of the world's largest auto manufacturers, today recalled nearly 5 million pickup trucks and sport utility vehicles in separate moves to respond to concerns of engine fires and problems with the power-steering system. The recall by Ford Motor Co., the fifth-largest auto industry recall in US history, involved 3.8 million pickups and SUVs from the 1994-2002 model years, including

the top-selling F-150 pickup.The National Highway Traffic Safety Administration (NHTSA) and Ford have been investigating complaints of engine fires linked to the cruise control switch system.

Toyota Motor Corp., meanwhile, recalled 978,000 sport utility vehicles and pickup trucks over complaints that a rod linking the steering wheel and the wheels could fracture when the steering wheel is turned while the vehicle is stopped. The affected Toyota vehicles include the 1990-1995 4 Runner SUV, 1989-1995 truck 4WD and 1993-1998 T-100 pickup.

In the Ford case, NHTSA said Wednesday it was reviewing 1,170 allegations of engine fires related to the vehicles and would continue a probe launched earlier this year. There have been allegations of three deaths in cases cited in news reports or lawsuits in Iowa, Georgia and Arkansas.

Ford's recall includes the 1994-2002 F-150, 1997-2002 Ford Expedition, 1998-2002 Lincoln Navigator and 1994-1996 Ford Bronco equipped with factory-installed speed control. It covers most of the vehicles being evaluated by NHTSA. Ford said its inquiry found brake fluid could leak through the cruise control's deactivation switch into the system's electrical components, leading to potential corrosion. That could lead to a buildup of electrical current that could cause overheating and a fire.

Cars or trucks, WELD - MECHANICAL OR ELECTRICAL ISSUES, the end results can be deadly.

2005: Filed under:

Automotive News

Ford recalling over 225,000 cars over fire risks

American auto giant Ford is finding itself in more trouble. If falling sales and dropping market share was not bad enough, it now has a huge PR crisis in its hand. The company is recalling over 225,000 vehicles over possible fire risks. These vehicles were sold in markets of US and Canada and include some popular vehicles like Ford Five Hundred sedan and Freestyle wagon. Most of the vehicles being recalled are from the 2005-model year and include the Crown Victoria, Lincoln Town Car, Mercury Grand Marquis and Montego sedans. The recall includes 127,493 Ford Five Hundred and Mercury Montego sedans and Freestyle wagons. These have issues with their straps that secure the fuel tank to the vehicle body.

Another recall includes 98,444 Crown Victoria, Lincoln Town Car, and Mercury Grand Marquis sedans. These recalls are related to the battery cable, which might scrape on an attaching bolt and could lead to a fire. This is bad time for such a publicity disaster for a company, which is suffering huge losses in its domestic market. And this latest recalls come just a few months after they had to recall nearly 4 million vehicles in September because of the risk of engine fires.

At the end of the day Joe, manufacturing defects are not a result of our robots or people on the shop floors, the defects are a result of inadequate design, poor engineering, poor manufacturing practices and inadequate quality control.

Vehicle fire data has some experts fuming.

Posted in the Sun, Dec. 11, 2005

By PAUL WENSKE.

ColumnistPartial Column.

Some safety experts are increasingly concerned that many vehicle fires are going unreported to government agencies. AAA in October drew attention to the danger of car fires by reporting that 520 persons died in highway vehicle fires in 2004 — more than the number who died in apartment fires.

The automobile association said there were more than 266,500 vehicle fires,

resulting in 1,300 injuries and nearly $1 billion in property damage.But Clarence Ditlow, head of the Center for Auto Safety, a Washington-based consumer advocacy group, said AAA’s fire figures were “just the tip of the iceberg.” An estimated 500 to 1,000 fatal accidents involving fires never get reported as fire-related deaths, said Kennerly Digges, president of the Motor Vehicle Fire Research Institute, an independent nonprofit group based in Charlottesville, Va, specializing in automobile fire safety research.

In September, Ford recalled cruise control switches on 3.8 million 1994-2002 Ford pickups and SUVs that can overheat. But critics think the system can be made better by digging deeper into the causes of vehicle fires. They say the government’s two main databases suffer from serious information gaps and miss many non-crash fires.

Some experts say the Fatality Analysis Reporting System database can miss incidents because it was designed only to collect data on fatal accidents on public highways. To be counted, a car must be “in transport” — in other words: moving. Cars catching fire in driveways, along the shoulders of roads or in garages were’t always counted. Many problems stem simply from a failure to report fires correctly, said James Fell, research director at the Pacific Institute for Research and Evaluation. Fell said as many as half of all states appeared to underreport car fire deaths, often by simply failing to include death certificates with police reports.

THE REAL FACTS RARELY COME TO THE SURFACE.....“If the police don’t list a fire in their report, the death does not get reported as a "fire-related death” Fell said.

But the reporting codes used by firefighters to report vehicle fires are the same ones used for fires in apartment complexes, homes and even skyscrapers. A country wide coding system specifically for car fires does not exist. Fires that start in cars but spread to houses, where they sometimes cause deaths, are reported as structural fires.

A local case illustrates just how easy it is for a car fire to go unreported.

Pam Tarr said her parent’s 2001 Buick LeSabre filled with smoke last year as they were driving near Kansas City. After pulling over, flames shot from the floor between the front and back seats. Tarr’s father died of a heart attack after exiting the vehicle. The fire department reported the fire but not the cause, and did not list the death as fire-related. Apparently, in part because the car was not moving, the fire and death do not appear in the National Transportation Safety Administration’s database. Kevin Stanley, the family’s attorney, said the lack of reporting shows that there “should be a priority to find what causes car fires. That isn’t done now.”

A note from Ed: If you are unfortunate enough to own one of the thousands of vehicles that could catch on fire due to the numerous issues that seem to occur mostly from manufacturing defects with the electrical system, fuel lines or fuel tanks, when the vehicle starts to burn there is only one logical thing that I would do. If my vehicle catches on fire, I will exit promptly, mutter some expletives about useless, f- - - - - g North American Manufacturing Managers and then let the vehicle burn to the ground. With the insurance proceeds I would likely buy a Toyota or Honda.

Common auto / truck frame welds.

With some welds I wanted to say, please don't drop those parts.

If you tried to create a weld like this with almost no weld fusion it would be a difficult task

According to Reuters:

Ford Quietly Fixing Expedition Weld Faults:

Ford, plagued by early quality problems with redesigned vehicles over the last two years, has been quietly fixing a defect on hundreds of new Expedition sport utility vehicles that could have led to an embarrassing recall. The problem involved faulty welding in the rear suspension area of early production models of the full-size SUV, which Ford began building in April at its Michigan Truck assembly plant outside Detroit. Ford held back the first month's production of 2003 Expedition and the similar Lincoln Navigator for extra quality checks and caught the problem before any vehicles were shipped to dealers. The work was being carried out in a hangar of the Willow Run airport near Ann Arbor, Michigan, which sits alongside a tightly secured parking field where Ford has held many of its new trucks, clad in white plastic sheeting, since April. Ford wanted to avoid the negative publicity that would have come with a recall after the recalls of the new Explorer in 2002 and the Escape in 2000.

Ford GM and Chrysler executive management could ask themselves a few simple questions.

What's happened to the more than a billion dollars your organizations

have spent on ISO, LEAN MFG DYNAMIC CONTROL PLANS. SIX SIGMA. TOPS. DOE. FMEA. KAIZEN. KANBAN. MRP. J.I.T. T.Q.M. SPC. POKE. YOKE. AND LAST BUT NOT LEAST THE BIG JOKE.

While your companies embraced the many available lean / manufacturing control programs or crutches that seem to be a requirement by organizations and individuals who lack manufacturing expertise, where were the;

[] professional managers that provided the required leadership. Managers that stated "the buck stops here". Managers that actually took ownership of the key manufacturing equipment in their facilities?

[] professional managers who had the ability to nurture their engineers and technicians to establish global, uniform Best Manufacturing and Quality Practices?[] professional managers who could instruct their engineers to implement Process Controls that would guarantee the desired daily quality and productivity?

[] professional mangers who knew what was required for an effective training program?

[] designers who took an interest in weld processes used on their parts and followed through on the components they designed and did not enable design dimensional deviations or inferior products to replace the products they specified?

[] manufacturing engineers that rolled up their sleeves and built the parts as specified?

[] the corporate executives who had the leadership and vision to build a safe, stylish, quality vehicle that required low fuel consumption and was good value for a consumers buck.

As these corporate guys pick up their annual bonus, someone should write on the back of there bonus checks that "responsibility for design, engineering and manufacturing always starts with the leadership in the corporate office"

For more than two decades it looked like the Big Three were intent on buiding Wall-Mart cars?

Hard to tell which one is which.

Questions for Auto / Truck Executives:[] Why do the majority of North American cars you build all look the same and look like they are in the right place when parked outside a Wall-mart store?

[] Why have your auto / truck product recall / warranty costs now surpassed the medical insurance benefits you pay your employee's?

[] When looking for across the board cost reductions, why do you focus on employee benefit costs or lower overseas labor costs and never focus on the dramatic cost savings that could be attained from manufacturing recall or warranty cost reductions?

[] Why do you continue to award your manufacturing management and supervision with obscene bonuses at a time when their manufacturing production efficiency is rarely attained without overtime premiums?

[] Why do so many of the managers and engineers you hire lack the ability or resources to build parts without extensive rework, parts that actually comply to the engineering design standards provided?[] Why do we keep letting your bean counters influence design, engineering and quality?

[] Why do so many of your plants lack the fundamental ability to establish Global Best Manufacturing Practices and implement effective shop floor Process Controls?

[] When did you stop valuing the opinions of your engineers, technicians and customers.

The following are typical examples of auto / truck MANUFACTURING MANAGEMENT problems that typically occur. If you wish to contribute your quality / productivity stories to this section or any of the data provided you believe is incorrect, contact ecraig@weldreality.com.

June 2006 or is it 2016?.

While Michigan and Ohio turn into a rust belt,

Ford looks to invest 9.2 Billion dollars in Mexico.

When he started Ford Motor company, Henry Ford's philosophy was to pay workers above the norm, and rely on efficient assembly of the quality, affordable cars he built. The high pay to the workers would then enable thosee employees to buy their own vehicles and so began the great American Dream.In 2006 as Ford shuts down American plants, Ford Motor company announces approx 9.2 billion dollar investment in Mexican plants.

Whats that American Dream?

Boys when you come home you will find great jobs available at new

companies like Wallmart and McDonalds.

More bad welds at Ford.

Thanks to inexperienced Ford manufacturing management and engineer, Ford is recalling 87,515 F-250, F-350, F-450 and F-550 trucks from the 2008 model year to fix improper seat welds. The recall is expected to begin on March 24.The National Highway Traffic Safety Administration's recall summary says "some 40 percent split and captain's chair driver seats, equipped with lumbar supports, may have improper welds at the joint of the seatback pivot bracket and the seatback frame. In the event of a crash, the seat side pivot bracket may crack or break, increasing the risk of injury to the seat occupant."

Ford Manufacturing Management Issues:

RECALL: 2004 Ford Ranger:

NHTSA Campaign Number: 04V331000 www.nhtsa.dot.gov

Manufacturer FORD MOTOR CO.

Recall Date: 07/14/2004

Potential Number Of Units Affected: 1395Description STRUCTURE: FRAME AND MEMBERS:UNDERBODY SHIELDS

Summary: ON CERTAIN PICKUP TRUCKS, THE FRAME MAY HAVE A CENTER RAIL SECTION FLANGE THAT WAS NOT FORMED PROPERLY. Consequence.... IN THE EVENT OF A SIDE IMPACT CRASH, THE FRAME RAIL COULD PUNCTURE THE FUEL TANK, RESULTING IN A FUEL LEAK THAT IN THE PRESENCE OF AN IGNITION SOURCE, COULD RESULT IN A FIRE.

Ford Manufacturing Management Issues:

2000: A judge in Alameda County, California ordered Ford Motor Company to recall millions of its vehicles (various models) made between 1983 and 1995 - due to faulty and potentially hazardous ignition switches (thick, or thin film type) which causes vehicles to stall out when they heat up during use. Ford denies that the switches are defective and promises to appeal the decision.

The affected vehicles include: 1994-2002 model F-150s, 1997-2002 Expeditions, 1998-2002 Navigators and 1994-1996 Broncos equipped with factory-installed speed control.

Ford Manufacturing Management Issues:

Ford Recalls 220,000 '05 Vehicles.

Nov 16, 2005 4:18 pm US / Eastern

WASHINGTON (AP) Ford Motor Co. recalled about 220,000 vehicles from the 2005 model year on Wednesday amid concerns that a battery cable was rubbing against the vehicle frame, potentially causing fires, and that a fuel tank strap could separate after logging tens of thousands of miles. The National Highway Traffic Safety Administration stated that so far it has received four reports of fires.

The company's investigation found that the manufacturer of the strap changed to a weaker grade of steel in December 2004, a grade that could not meet Ford's durability requirements. Ford declined to disclose the supplier's identity.

Note from Ed. So much for manufacturing management standards & the millions Ford & its suppliers spent on ISO.

IF I OWNED A FORD VAN, RATHER THAN PARK IT IN THE GARAGE

I WOULD LIKELY PARK IT NEAR A FIRE HYDRANT:Ford Motor Co. issues a pair of safety recalls on certain '03-'04 E-Series full size vans and is asking dealers to ensure that some of the vehicles not be parked in enclosed structures due to fears of unattended engine fires. The auto maker is calling back E-Series Econoline work vans and Club Wagon passenger vans built between April 23, 2002, and April 30, 2004. The recalls regard two different safety problems, both of which could potentially lead to vehicle fires, according to two recall notices provided to

Ward's.All affected vehicles were built at Ford's Lorain, OH, assembly operation. About 235,000 Econoline vans built between 2002 and 2003 are being called back to replace defective parts associated with the vehicle's antilock brake system. A diode in the ABS could short itself out, leading to overheating even in unattended vehicles. Because of the risk of unattended vehicle fires, Ford is warning against parking affected vehicles in enclosed structures, such as garages and parking structures.

Additionally, Ford is recalling all E-Series vans with gasoline engines built between April 2002 and April 2004, including the affected Econolines, because air-filter paper was not properly manufactured. The paper is unable to prevent the filter from igniting when hot particles in the engine air system contact it, therefore leading to potential engine fires.

IT DOE'S NOT SEEM TO MATTER IF IT'S

MADE BY THE CANADIANS OR THE YANKS.

The Ford Windstar and Manufacturing Management:We purchased a brand new Canadian made Ford Windstar in 1999. When we drove it off the lot we noticed mechanical problems already occurring.

[a] The cruise control was not hooked up properly, we should of known then we were in for trouble.

[b] We have had a continual ping in the engine that the Ford motor company has told us we basically have to live with. "We can't seem to find the problem".

[c] When the car was two years old we noticed a leak coming from the back window. We took it in to Ford and they said not to worry it was just a bad weld and they fixed it. Little did we know that the moisture had already got into the wiring.

[d] We now are experiencing severe problems with the electrical system.

[e] The automatic sliding door works sparingly.

[f] The key faub no longer works for the driver side door.

[g] The lights and fans sporadically turn on and off, and the worst problem is that there is a constant drain on our battery because of shorts in the wiring that Ford could not (would not?) diagnose.

[h] We continually have to charge our battery nightly so we can make it through the day without getting stranded.

As we gave up on Ford, we took the Windstar to a reputable car mechanic and within two hours he was able to diagnose the problem and how we should go about fixing it. The mechanics advice, trade the Windstar in on a none Ford product. Ford will no longer be getting our business or our friends. Thanks for a lousy product Ford! Never Again. David Bianchini.

Ford Manufacturing Management Issues:

IT'S 2004. FORD ENGINEERS MAKE A STARTLING NEW DISCOVERY

"SALT CAUSES CORROSION":From Auto.com,

Jul 16 2004.

Ford launches at least its third Taurus and Sable recall in 2004, following a spate of actions earlier this month. Ford Motor Co. reportedly recalls some 899,060 Taurus and Mercury Sable sedans registered in 22 states that are located in what is considered cold weather regions, according to the National Highway Traffic Safety Administration. Reuters says the recall includes '99, '00 and '01 vehicles with defective springs that potentially could sever due to corrosion, leading to tire punctures. The use of salt on icy roads is a major cause of corrosion and Ford dealers are asked to install protective shields over the springs.The action marks at least the third Taurus / Sable recall this year and Ford's fifth separate action this month, which include eight different models.

Ford Manufacturing Management Issues:

It's been going on for decades:

[] 1991. Ford Explorer NHTSA Recall ID Number: 91V026000

STRUCTURE:BODY:BUMPERS Potential Units Affected: 220000 Summary: REAR BUMPER REINFORCEMENT MAY BE SUBJECT TO FATIGUE CRACKING UNDER EXTENDED TRAILER TOW SERVICE WHEN USING A BUMPER-MOUNTED TRAILER HITCH BALL.

Ford Manufacturing Management Issues:

2002. The Crown Victoria (Ford Motor, Company) is reported to be suffering rear gas tank / accident / safety issues. Two bolts may puncture the gas tank upon rear end collisions.

Note from Ed: For Gods sake Ford you have been having gas tank reliabilty issues for at least 50 years, could you put a little focus on building a simple, strong metal container. A rubber container inside the fuel tank was an idea presented to Ford in the 1960s. This product was designed to contain the gas if the gas tank was damaged in a collision, it was rejected, considered too costly at approx. $5.

Cars, Trucks and

Mangement Controls:

Ford Manufacturing Management Issues:

Monday, November 27, 2000

By JUSTIN HYDE

THE ASSOCIATED PRESS DETROIT -

For the fifth time in a little over a year, Ford Motor Co. told it's dealers either to prohibit sales or test-drives of its new Escape sport utility vehicles while they're checked for safety-related problems. The latest notice to dealers was sent Nov. 18, affecting 51,022 Escapes and about 24,000 Mazda Tributes, which share basic parts with the Escape and are built in the same plant in Claycomo, Mo. Of those, 27,516 Escapes and about 12,500 Tributes have already been sold. Ford spokesman Mike Vaughn said dealers were told to check for damaged windshield wiper link ball sockets and replace them if necessary. If the sockets were improperly built, the wipers could stop working. Parts to fix the problem "are in the pipeline" to dealers, Vaughn said. Previous warnings to dealers on the Escape and Tribute, both of which only went on the market in August, have included warnings about the;

[] steering wheel coming off,

[] leaky fuel lines,

[] incorrect wheel hubs,

[] and a problem with the cruise control that could cause the throttle to stick.

THE BIG THREE INSIST THAT THEIR WELDED

PARTS ARE ONLY WELDED WITH ROBOTS.

WAIT TILL YOU SEE THE MANUAL WELD REPAIRS.

It's ironic that on the one hand we have the major auto / truck companies providing a logical mandate which insists that arc welds on cars and trucks will only be made by robots. Its not dawned on these companies that people who program robots need process control expertise. For more than two decades the majority of the companies that use robots will daily allow "unqualified" robot operators, programmers or maintenance personnel to daily make "unqualified" robot weld parameter changes to "unqualified" robot welded components. And then of course they will allow "unqualified" manual welders to make the "unqualified" manual weld repairs.

Ford Manufacturing Management Issues:

[] 1991 Ford Explorer. NHTSA Recall ID Number: 91V025000

FUEL SYSTEM, GASOLINE:STORAGE:TANK ASSEMBLY Potential Units Affected: 18000 Summary: THE HOT PLATE WELD WHICH ATTACHES THE VAPOR VENT VALVE CARRIER TO THE TOP OF THE PLASTIC FUEL TANK MAY PARTIALLY FRACTURE, ALLOWING VAPOR OF FUEL TO ESCAPE FROM THE TOP OF THE TANK. Consequence: THE ESCAPED VAPOR OR LEAKED FUEL COULD CAUSE A FIRE IN THE PRESENCE OF A SOURCE OF IGNITION.

Hey Yanks, you don't need to visit Iraq to find those elusive

weapons of mass destruction,

simply visit your nearest American new car showroom?

[] 2002 AeroStar Van.

A report suggests that the placement of the pressurized fuel line and strategic fittings near the exhaust system or high heat features may contribute to the potential for vehicular fires.

Plant and corporate manufacturing management would do well to remember what Harry Truman or Henry Ford once might have said.