|

|

Welcome to the world's largest web site on the Pulsed MIG Weld tips and advice. This web site was first established in 1997 by E Craig.

Contact . ecraig@weldreality.com. As changes too the site are frequent, please refresh.

Pulsed MIG weld issues and weld resolutions.

|

For almost three decades, Pulsed MIG equipment that typically has cost from six to fifthteen thousand dollars,

when used on manual "steel welds" has often caused more weld issues than resolutions.

While at this site, you may also have an interest in the MIG Equipment Section, which for more than two decades has provided extensive data on global Pulsed MIG equipment weld

performance and the numerous weld issues that the MIG equipment generated.

In the 1990 to around 2015 period, in North America, Japan and Europe and ironically in the third world countries where weld labor costs were a few dollars per day, you would find that the majority of the large weld - fabrication companies welding STEELS, were demanding costly, useless pulsed MIG equipment that typically cost $6,000 to $15.000 per-unit. (regular CV MIG power sources were typically $2000 to $4000 per-unit). The weld reality at that time, and as it's been for approx. 30 years, was when MIG welding most steel weld applications, (not aluminum.) was that most of the costly pulsed MIG weld equipment purchased offered nothing more than a metal container, full of cmplex circuit boards that offered little more than electronic bells and whistles that provided no real practical weld quality or productivity benefits. .

WELD REALITY FACT: For at least three decades in manual or robot weld cells, in contrast to the much lower cost, more durable CV MIG units available, Pulsed MIG units were usually causing more weld issues than providing weld benefits. The fact that this equipment was purchased without logical justification is a sad statement and a reflection of the lack of management / supervision weld process control expertise. This is an expertise that has been lacking in most global weld shop front offices for decades.

WELD REALITY FACT: It's 2018, and in the last three decades, the extensive growth of the costly pulsed MIG equipment for steel welds had more to do with an industry that too often relies on weld salesmen for process advice, than it had to do with the weld shop attaining real world MIG weld quality or weld productivity benefits.

Even Weld Technology Changes with Time:

In 2018, from my perspective there is at least one "cost effective" Pulsed MIG power source available

that actually can provide real world weld benefits for a few steels & many alum. weld applications.

The best pulsed equipment that I worked on almost 15 years ago, (used for my water wall cladding patent) and I

believe still

the best most cost effective pulsed MIG equipment available in 2018, is mfg. by OTC Daihen.

|

.

|

.

A QUESTION THAT COULD BE ASKED IN ANY GLOBAL WELD SHOP:

DO THOSE THAT MAKE WELD DECISIONS KNOW WITH THEIR ALUMINUM OR STEEL PULSED MIG WELDS, HOW WITHOUT PLAYING AROUND WITH THE WELD CONTROLS TO INSTANTLY PROVIDE THE PULSED OR CV MIG EQUIP. SETTINGS THAT WILL ENABLE OPTIMIZED WELD QUALITY - PRODUCTIVITY ON ANY APPLICATION. AND JUST AS IMPORTANT, ARE THE WELD PERSONNEL AWARE WHEN TO SWITCH THE PULSED MODE OFF AND USE ALTERNATIVE MIG WELD TRANSFER MODES AND THEIR REQUIRED OPTIMUM WELD SETTINGS?

My Weld Process Controls - Best Weld Practices, Self Teaching / Training Resources.

MIG WELDING PROCESS CONTROL QUESTION:

Would the weld personnel in the weld shops you have worked at be aware that when MIG welding the common 5XXX series aluminum, know when to switch the pulsed mode off, and why they may need to do it?

|

|

.

MIG WELDING PROCESS CONTROL QUESTION.

Do the front office weld decision makers or welders in the shop know when using the Pulsed MIG process, what steps are necessary to improve pulsed weld fusion on those > 3/16 steel welds?

PULSED MIG WELD QUALITY CONCERNS FOR PARTS > 3/16, (> 5 mm):

2018: As its been for decades, in contrast to the regular open arc Spray transfer weld mode available from the CV. MIG equipment, the Pulsed MIG process will on many welded parts > 5 mm, produce pulsed welds with inferior weld fusion and sometimes more weld porosity.

The reason for the Pulsed MIG weld fusion and porosity concerns on the thicker steels is a simple one. The open arc Pulsed MIG welds spend 50% of their arc on time in a low Back Ground (BG) current that could be around 100 amps. The low BG current takes energy from the arc plasma. In contrast, the arc energy is higher and the plasma energy more consistent with the conventional Spray weld. For those that want proof of the pulsed weld quality concerns, it takes five minutes and the following steps.

Spray transfer, more constant arc energy than Pulsed.

LOGICAL FIRST STEP FOR NEW PART. CHECK THE WELD FUSION ON SCRAP WITH THE MIG WELD TRANSFER MODE SELECTED:

- First step is to make sure the weld personnel testing the weld transfer modes are trained to set optimum MIG Spray setting. You know where to purchase that process self teaching / training resource.

- On clean, (no mill scale), 3/8 to 1/2, (10 - 12 mm) carbon steel test plates, have the welders produce a horizontal, single pass, 1/4, (6 mm), spray fillet weld approx. 6 inch long. Use an 0.045 (1.2mm) E70S-X wire set at the optimum Spray wire feed. 420 ipm. Approx. 28 - 30 volts.

- Then on a new COLD test sample, make the same fillet weld with the pulsed mode. Important use the same wire feed setting. The pulsed welds typically requires 24 - 27 volts.

- Section both the Spray and Pulsed welds in the middle of the fillets.

- Examine the side wall - root weld fusion depth, and also porosity content in both the weld cross sections.

- If you have fine tuned the voltage on both welds, there should be no spatter with both weld samples.

- You should find superior weld fusion and superior weld surface with the CV Spray weld.

2018:REAL WORLD PULSED MIG WELD BENEFITS ATTAINED FROM SOME PULSED EQUIPMENT.:

PULSED MIG AND WELD APPLICATION POTENTIAL:

In contrast to open arc MIG Spray, and the Short Circuit mode with it's arc on - arc off, the most important characteristic of a Pulsed MIG weld, is it's potential for lower open arc MIG weld energy than possible with any spray weld. This unique pulsed arc attribute can provide extensive weld quality - productivity benefits especially on thin steel <3/16 welds. Also of course, pulsed is especially beneficial on most, (not all) aluminum, welds especially alum. parts up to 1/4 (6mm).

Note" With the 5XXX alum. series MIG welds, you may get a better oxide cleaning action and superior weld fusion from switchong CV.Spray. The OTC pulsed unit that I tested also enabled from open root to cap "all position welds" on most metals.PULSED MIG POWER SOURCE OPTIONS & WELD AUTOMATION BENEFITS:

Pulsed MIG Inverter equipment features typically should also offer more ways to control the pulsed MIG welds. For example the pulsed mode may enable control of the weld starts & the weld ends, two weld locations where many MIG weld defects will occur. Also note, Pulsed MIG weld fusion potential is further enhanced with the use of automated welds. For example, all position, automated pipe welds, in which the MIG wire stickout, the weld travel speeds, and the weld weaves controls further enhance the pulsed MIG weld fusion capability.

PULSED AND STABLE LOW AMP CAPABILITY: The pulsed equipment may also offer in contrast to low amp, low volt short circuit, a modified improved low amp / low volt short circuit mode. Also very low amp, low volts DC pulsed parameters may be offered. Both low energy weld modes may be suited to very thin parts, or for all position, open root steel pipe welds. As these weld modes become common the traditional low energy MIG modes such as the Miller RMD and Lincoln STT are no longer unique and are not necessary for any gauge welds or open root, all position pipe welds.

TWO COMMON WORDS USED IN GLOBAL WELD SHOPS ARE?

WELDING PROCESS CONTROL QUESTION:

Do your weld personnel have the ability to walk up to any pulsed unit and instantly set pulsed parameters for an all position, open root steel pipe weld and then set for that 16 gauge (1/16) lap weld? If you don't believe your weld personnel should be "playing around" with weld controls and you would like MIG weld process control expertise, there is only one resource that provides it.

My MIG - TIG - FCAW process controls - best weld practice - self teaching and training resource is here.

For more than 30 years it was my job to evaluate MIG equipment and consumables for some

of the worlds largest MIG equipment manufactures and sellers, Airgas, AGA, Praxair, Liquid Carbonic.

.

Can you identify which of these MIG power

sources provided no real world weld benefits?

OVER THREE DECADES, MANY WELD SHOP MANAGERS, SUPERVISORS AND ENGINEERS PURCHASED THE MORE COSTLY, MORE COMPLEX PULSED MIG EQUIPMENT WITH GREAT ANTICIPATION FOR IMPROVEMENTS IN THEIR MIG WELD QUALITY. SIMPLY BECAUSE THEIR "PLAY AROUND" WITH THE WELD CONTROLS WELDERS WERE NOT AWARE OF HOW TO GET OPTIMUM MIG RESULTS FROM THE EASIER TO USE, TWO CONTROL, LOWER COST, MORE DURABLE CV. MIG EQUIPMENT.

The answer to above question on MIG power sources, was ALL.

MIG WELDING PROCESS CONTROL QUESTION. Before a weld shop considers purchasing MIG weld equipment with more weld controls and options than the traditional CV MIG weld equipment they already own, do you think the weld shop front office or the welders should have the ability to walk up to that standard CV MIG unit with it's two controls and with the common 0.035 (1mm) steel E70S-6 MIG wire, and an argon 10 to 20% CO2 gas mix, set the SPRAY TRANSFER start point VOLTAGE and WIRE FEED RATE?

As weld process expertise is something poorly understood and rarely discussed in weld shops, optimum MIG Spray & Short Circuit welds from low cost MIG equipment were rarely attained by weld personnel that lacked MIG process control - best practice expertise.

NORMAL WELD SHOP RESPONSE TO THE WELD PROCESS EXPERTISE QUESTION: "WELL I DONT KNOW ABOUT WELD PROCESS CONTROL EXPERTISE BUT SOME OF OUR WELDERS HAVE BEEN MIG WELDING FOR 20 PLUS YEARS".

Note for managers: Weld skills and time served as a welder, has nothing to do with Weld Process Control expertise.

It's a pity that the majority of AWS weld inspection person ell that have the ability to recognize

and report on weld defects, but thanks to the general lack of management weld process ownership and apathy, these individuals have not been provided the more cost effective training on the weld process controls & best weld practice expertise that would enable them to assist them in preventing those weld defects.

That pulsed weld fusion we are getting now is nothing like the weld fusion

attained two years ago with that pulsed weld qualification we did. I wonder why?.

WELD PROCEDURE CONFORMITY & CONTINUITY FROM ONE PULSED POWER SOURCE TO THE NEXT.. A note to QA management and inspection personnel. As the weld parameters and weld energy can dramatically change with different Pulsed MIG power sources and with Pulsed equipment that has simply undergone circuit board changes from one years model to the next,:

Note: Your original Pulsed MIG weld procedure qualification data may mean little when using updated or different pulsed MIG equipment.THERE HAS BEEN MILLIONS OF CV MIG WELD PROCEDURES PRODUCED BY THE WELD INDUSTRY OVER THE LAST FEW DECADES. THE CV PROCEDURES ARE USUALLY TUCKED AWAY IN A CABINET IN THE QA MANAGERS OFFICE. THOSE MIG PROCEDURES TYPICALLY REQUIRED A SPRAY OR SHORT CIRCUIT WELD, TWO WELD TRANSFER MODES THAT WOULD HAVE HAD MINIMAL WELD ENERGY CHANGES WITH A CHANGE IN THE CV WELD EQUIPMENT SOLD BETWEEN 1968 AND 2018.

There should always be weld liability concerns

from management weld process ignorance.

THERE WILL ALSO BE WELD LIABILTY CONCERNS GENERATED WITH THE WELD

DIFFERENCES THAT RESULTS FROM DIFFERENT PULSED MIG EQUIP.

MORE ON PULSED WELD LIABILITY CONCERNS. I predict that not worrying about weld fusion changes from the ever changing pulsed MIG equipment, and not re-qualifying the pulsed welds when new or different pulsed MIG equipment is utilized, will be just another one of those weld shop concerns that management with their heads in the sand will not be aware about, and of course one day, there will be dramatic costly weld failure, weld recall and weld liability consequences.

MIG WELDING PROCESS CONTROL QUESTION. Why with any MIG or gas shielded flux cored weld procedure is it important that the one constant in the procedure is always the wire feed speed?

2018: Some of the available, present day pulsed MIG equipment should have a good DC / Hz pulsed mode that when used with weld process expertise provides a sound process for most all position pipe GROOVE fill pass welds.Note: Please be aware that no manual or automated arc weld process can provide the pipe weld quality that is attained with the TiP TiG process.

.

This is the world's most cost effective pulsed MIG equipment

for manual or automated welds and costs approx. $7000.

Weld shop employees simply cannot fully enable the optimum weld application range or the maximum weld quality - productivity potential from any pulsed MIG unit without MIG weld process control & best weld practice expertise.

This expertise costs approx. $300. My Pulsed MIG process control self teaching - training programs, reduces and simplifies pulsed MIG weld setting for any pulsed and none pulsed weld applications.

Of course the welders should be aware that the new

electronic MIG equipment requires some bloody care and respect.

In robot cells, Pulsed MIG weld equipment repairs can be a major concern.

PULSED MIG EQUIPMENT DURABILITY - RELIABILITY CONCERNS.

That new, costly pulsed MIG weld equipment depending on the pulsed equip. mfg. may just about get through it's short warranty period without circuit board or electronic issues that may impact a companies weld quality - productivity and profits. When the pulsed MIG unit does require repairs, a company should expect to pay thousands of dollars, and pray it won't take more than a month or two to repair. If you are purchasing a few robots and the power source is pulsed ensure you have a spare. If you are purchasing Pulsed equip. for manual welds, the equipment longevity will increase if the equip. is cleaned (air blow out) frequently and when not in use the equipment is covered.

Please also be aware that a company will add to the pulsed equipment longevity and durability concerns when the pulsed equipment purchased was made in a third world country.

Note: You are wasting money purchasing pulsed MIG equipment for steel weld repairs, a low cost 250 amp CV MIG power source using an 0.035 wire with a short circuit or spray setting is all you need.

.

Yes in 2018, some (not all) pulsed MIG units now finally offer some real world weld quality - productivity benefits for "steels", however this equipment can also offer more unnecessary bells and whistles that simply add to the weld shop process confusion.

Pulsed MIG units and three part MIG gas mixes for steel welds,

two products that drove up

the equip. and consumable

sales prices

and profits, and for

many

decades, the best way to sell them was with weld sales BS.

As below, why has Pulsed MIG equip, be more successful on automated

pipe welds than it has on manual MIG pipe welds?.

Automation when used correctly should enhance any arc weld process.

MIG WELD PROCESS CONTROL QUESTION:

We are a pipe shop and we read in weld magazines about the sucess of pulsed MIG equipment on automated PIPE weld applications, but we have little success on our all position, steel pipe, "manual" pulsed MIG welds. why the difference?Answer: It's important to remember, with mechanized automated pulsed MIG pipe welds, that the equipment may be providing additional weld control features such as volt or current energy spikes. These spikes can be applied to the weld weave dwell times that coincide with the pipe side wall fusion locations. The increased energy spikes & weave dwell times can improve the pipe side wall weld fusion. The controlled pulsed MIG pipe weld / weave speeds, the controlled wire stick out length also has a lot to do with success of the mechanized pulsed MIG process on pipe line welds.

|

.

Gas Shielded Flux Cored, a good process to attain the

desired weld fusion with all position welds.

However gas shielded flux cored is also a good process that generates

weld slag inclusions, worm tracks, weld porosity and weld fume issues.

WHAT ABOUT FLUX CORED WIRES USED ON THAT PULSED MIG EQUIPMENT? Weld shops should give some consideration to the reality that all gas shielded flux core wires were developed and weld tested with traditional 350 - 450 amp. CV MIG equipment that had a s moderate slope output. The weld energy that was delivered by the CV equipment for a specific recommended flux cored wire feed setting was important, especially when dealing with the fast freeze, all position wires or the basic slag. (thicker slag) wires used for flat position welds. If you use Pulsed MIG equipment for the flux cored wires, and switch the pulsed equipment to it's CV MIG mode, its interesting to note that the slope output on the pulsed MIG equipment is typically steeper than regular CV equipment, the end result is the pulsed unit will typically deliver less weld current and be less responsive to arc length changes. So beware, those faster freeze pulsed MIG equipment flux cored welds may generate increased weld fusion, porosity and trapped slag concerns.

FOR DECADES DIFFERENT MIG EQUIPMENT MFGS HAVE PROVIDED 300 - 450 AMP CV, MIG POWER SOURCES THAT TYPICALLY HAD SIMILAR SLOPES, AND THEREFORE FOR DECADES, CV MIG EQUIPMENT PROVIDED REASONABLY CONSISTENT WELD RESULTS.

TODAY THE MILLER DELTA MIG WELD EQUIP, AND IN THE OLD DAYS, THE LINDE SVI EQUIPMENT, HAVE BEEN THE BEST PERFORMING EQUIPMENT WITH LOW COST, CV EQUIPMENT, LIFE FOR THE WELD SHOP COULD BE SIMPLE, THAT IS IF MANAGEMENT WERE AWARE THAT THEY SHOULD PROVIDE THEIR WELD PERSONNEL WITH MIG PROCESS CONTROL - BEST WELD PRACTICE TRAINING. WITH THE TWO SIMPLE CONTROLS, THE DURABLE, LOW COST, CV EQUIPMENT COULD PROVIDE SHORT CIRCUIT, GLOBULAR OR SPRAY TRANSFER THAT WOULD PROVIDE LOW,- MEDIUM AND - HIGH ENERGY MIG WELDS SUITED TO 99% OF THE GLOBAL WELD APPICATIONS.

What is the best manual arc weld process for most pipe line welds?

For decades SMAW & Flux Cored were the

most common processes for large pipe welds.

THERE ARE REASONS WHY PULSED MIG CAN CREATE WELD FUSION CONCERNS ON MANUAL STEEL PIPE WELDS, BUT THE PROCESS CAN BE MORE SUCESSFULL ON AUTOMATED, PULSED MIG PIPE WELDS:

Large pipe line weld projects especially in the oil industry will often use a mechanized, multi-torch, pulsed MIG or flux cored weld system. The controls on the automated equipment will typically have additional, sophisticated, electronic controls that can enhance the performance from the standard pulsed MIG power source.

For mechanized pipe OPEN root welds, either the MIG CMT - STT - RMD modes will typically be selected, these are weld transfer modes that are now redundant, that is if you buy the right pulsed equip. For the pipe groove fill pass welds, the more conventional DC pulse mode will be selected, with or without Hz control. In addition to the pulsed power source you may also find the pulsed equipment has controls that enable unique pipe weld attributes. For example the equipment may with a weave weld have the capability to provide a current or volt spike during the weld edge dwell time in the weld weave cycles.

Vee and J groove pipe welds have simple weld requirements. Moderate MIG weld energy is required across the hot groove weld surface, and higher weld energy with the weld edge well times is beneficial when applied to any Vee or J groove side walls. The thicker the pipe, the higher the side wall energy will be required. The controlled pulsed MIG weaves, controlled WSO, controlled travel rates, and the weave dwell energy spikes can overcome the common, manual pulsed MIG lack of side wall fusion.

2103: LETS GET BACK TO WELD SHOP WELD REALITY.

In 2018 we now have in North America, a very few pulsed MIG power sources that actually work in a consistent manner and provide real world measurable weld benefits on steels, (of course aluminum is not included, its also important to note that even fewer pulsed units will get through their 36 month (or less) limited warranty period without costly circuit board issues. The question that needs to be asked when selecting pulsed for manual steel and alloy steel applications was the purchase of this sensitive process justified in contrast to what can be attained from the lower cost CV MIG equipment.

There has always been obvious weld benefits attained from pulsed MIG on aluminum welds that require lower weld energy than steel welds. For example, gage aluminum welds can benefit from less weld energy than delivered by low spray settings, and specific MIG stainless welds will benefit from an open arc mode that enables lower weld heat than spray, a benefit that will reduce distortion potential. Remember the key benefit of a MIG weld mode is the ability to provide consistent weld fusion, and on most weld applications, spray transfer will provide superior weld fusion than pulsed. Always remember that Pulsed MIG is a process which spends 50% of its time at a back ground weld current of usually less than 100 amps a factor that does not help weld fusion on sluggish alloy welds. The pulsed process is also beneficial when welding alloys that have poor weld transfer characteristics when welded with the conventional short circuit or spray transfer mode.

2010: In the last two decades, as many pipe welds shops found out, when pulsed MIG is used for "manual" pipe welds that require "100% X-Rays", lack of weld fusion may become a common weld defect especially on wall thickness > 12mm. In contrast to SMAW used for pipe welds, each hour pulsed MIG will typically provides at least 7 - 10 times more weld and therefore pulsed MIG on pipe is considered a high deposition process that creates much faster weld speeds than traditional TIG and SMAW. Those high weld speeds play a key role in creating the lack of Pulsed MIG weld fusion issues.

Any experienced weld person would be aware that

the outside appearance of most MIG and

Flux Cored welds is not that relevant.

.

MANY TALK THE PULSED MIG TALK, WITHOUT DOING THE PULSED MIG WALK.

If a company provides what they believe is an optimum, single pass, pulsed MIG, 7 - 9 mm fillet weld on 3/8 (9.6mm) steel plates, and then provides a macro section at the center of the fillet weld, they should not be surprised to find either marginal or lack of side wall weld fusion. After the numerous macro weld evaluations that I have performed, there is only one conclusion. With the pulsed MIG process, you have a weld process that when welding parts > 6 mm, the welds will have a poor ratio of weld energy to the weld deposition, to the weld mass, and to the weld speeds utilized. Also with manual pulsed MIG welds, that weld energy is further negatively influenced or the weld transfer disrupted by mill scale, by the manual wire stick out variations, and by the many different weld techniques that each manual welder brings to the pulsed weld..

.

|

.

.

|

For ABB I did welds like this with pulsed MIG and a 7 axis robot, and

passed all the ASME Sect 1X. X-Ray requirements, and that was in the 1990s.

|

IN CONTRAST, THE COMPLEXITY OF SHORT WELD CYCLE TIMES THAT ARE INVOLVED WITH SMALL DIAMETER PIPE AND TUBE WELDS, CREATING OPTIMUM, CODE QUALITY, MIG - FLUX CORED WELDS ON PIPE DIAMETERS OVER 15 cm SHOULD ALWAYS BE AN EASY TASK

I remember in the 1990's, when the inexperienced management team at USA. ASEA Brown Boveri, one of the world's largest engineering companies decided to purchase a seven axis robot to pulsed MIG weld the boiler tubes to header applications that this company produced. The above picture is not the parts welded but similar application. The boiler header pipes were approx. 8 - 10 diameter, typically 20 to 40 feet long, while the tubes were 2 - 3 inch diameter with much thinner wall than the header. The robot traversed on a track placed on the other side of the header. These complex, ASME code welds were typically carried out by the highest skilled manual TIG welders. I won't go into the poor management decision to have selected a robot and the pulsed MIG process for these welds, however I would like to tell you about the pulsed MIG welds I produced on this robot application.

For each boiler tube to head weld, two robot pulsed MIG weld layers were required to fill the grooves and produce the fillet around the header. The pulsed MIG welds had to pass 100 X-Ray as per the ASME requirements. As the robot could not go 360 degrees around the tubes each of the two weld layers was made with four passes so four weld start - stops was required for one layer, with a total of 8 start - stops for the completed 2 weld layers, by the way no grinding or human involvement was allowed for the weld layers..

Normally a highly skilled manual TIG applications. It was a MIG welding challenge with the poor performing 1990s pulsed MIG equipment and a robot. |

AT THE TIME I WAS ASKED BY THE ASEA BROWN BOVERI MANAGEMENT, TO RESOLVE THEIR NEW ROBOT TUBE TO HEADER PULSED MIG WELD ISSUES, THE PULSED TECHNOLOGY HAD BEEN AROUND FOR LESS THAN A DECADE. AT THIS TIME, THE ELECTRONICS IN ALL PULSED MIG EQUIP WERE SIMPLY NOT UP TO THE TASK OF PROVIDING STABLE WELD TRANSFER.

Can you remember the poor performance of computers in the early 1990s? well I want you to try and imagine how bad the global electronic pulsed MIG equipment was at that time, and by the way not much improved in 2014.

The bottom line with the ABB application was that I had a sophisticated robot attached to a poor performing, inconsistent - erratic pulsed power source, and yet I had to provide consistent quality to the demanding ASME boiler code. The difficult access, vertical up, tube to header welds were also made on two very different part thicknesses. With the small diameter tube welds I had To get consistent fusion on the thicker header pipe, along with 8 weld starts and 8 weld stops that required perfect weld tie-ins on the tube welds.

REMEMBER WITH AUTOMATED, SMALL DIAMETER PIPE - TUBE MIG WELDED APPLICATIONS, THE SHORT WELD LENGTHS HAVE WELD ARC ON TIMES THAT MAY BE MEASURED IN A FEW SECONDS. THESE WELD RELY ON WELD EQUIPMENT AND CONTROLS THAT CAN DELIVER WELD START DATA - WELD DATA - AND WELD END DATA OFTEN WITHIN A FEW SECONDS. THE REALITY IN 2014 FEW AUTOMATED WELD UNITS ARE GOOD AT PROVIDING THIS FUNCTION, SO IMAGINE WHAT I HAD TO WORK WITH IN THE 1990s.

.

|

All the boiler tube to header welds were evaluated with X-Rays, and all that was needed was one poor weld tie or an indication of lack of fusion and the weld was as a failure requiring extensive time for weld repairs by the manual TIG welders. The ABB technician was trained on the robot and pulsed MIG equipment but failed to meet the weld challenge of producing one acceptable weld. The robot company and the pulsed MIG equipment mfg also could not make the welds meet the code requirements. Rather than seeking my advice before they purchased the robot, the inexperienced managers and engineers discussed the application with the companies who sold the robots and pulsed MIG equipment, I was then called in when they failed to meet the ASME weld requirements.

It was a difficult task, however I had a good robot and I could use my MIG weld process control - best practice expertise to make these welds work. Within a week, I produced in an eight hour shift, robot weld quality that required no weld rework and the weld quality was equal to that attained by the manual, highly skilled TIG welders. How did i solve the common pulsed MIG weld fusion - weld tie in issues?. For the side wall weld fusion I used robot weave dwell times and kept the pulsed MIG weld mass as thin as possible. For the weld start - stop tie-ins, with the robot weld end - start data, I used low wire feed than the weld with higher weld voltage which with carefully selected dwell time provided good tie ins, (creating a dwell time energy spike) which is similar to what is today, 18 years later is being used on pipe line welds with much more sophisticated, pulsed MIG equipment and controls. I trained a technician at ABB to make those robot welds. I also informed the management that only having one person trained for this complex application was not a good idea. Within a year the technician quit, and the robot became a place for dust to settle. Eventually the ABB management gave up and that costly robot was put out to pasture. In 2014, these boiler tube to header welds would still be a high risk robot application especially when you can now do these welds with the easy to use manual or automated TiP TiG process.

| 1990s.. Ed (left - right) comparing MIG short circuit versus the STT and RMD MIG weld modes on Imperial Oil, natural gas pipe welds. |

.

|

.

.

WELD CODES OFTEN PROVIDE MORE MIG - FLUX CORED

WELD MYTHS THAN WELD REALITY.

When it comes to MIG and flux cored welds, rather than providing practical weld process resolutions, most codes that are relevant to pipe welds will typically provide inadequate MIG and Flux cored process information, and much of the information presented over the last three decades has simply added to the global weld process myths and confusion.

Welding decision makers often look codes such as AWS - API and - ASME to provide practical, pipe weld advice and recommendations. Those individuals (especially QA personnel) that that put their faith in the codes that are governing the specific weld applications they are working on, need to be aware of a little weld reality. The weld information in most codes has frequently been written or influenced by code committee individuals who had more sales expertise than MIG - Flux Cored weld process control & best practices / application expertise.

50 YEARS AFTER THE INTRODUCTION OF THE "MIG PROCESS", AND 35 YEARS AFTER THE INTRODUCTION OF FLUX CORED ELECTRODES, THE PRIMARY WELD CODES WHEN ADVISING ON THESE PROCESSES STILL CREATE CONFUSION AND TOO MANY QUESTIONS.

API. 5.2.3 Pulsed Gas Metal Arc Welding (GMAW-P. This code states that the pulsed process may be used for any material thickness and whenever the welding system is changed or the settings on existing equipment are "significantly altered," then the fabricator should verify the weld properties. The extent of verification or testing should be as agreed between the purchaser and fabricator.

Ed response. In a world in which black and white logic should apply to engineering standards especially with critical pipe welds, what the hell does "significantly altered" mean?. In contrast to the traditional, two control, MIG or flux cored weld process, there are many weld essential variables that can be readily changed when utilizing the pulsed MIG mode. While the API code warns against a "SIGNIFICANT CHANGE" in a pulsed settings", the real world weld decision maker needs to be aware that an insignificant, small parameter change with the highly sensitive, manual pulsed MIG mode, can have a significant influence on the weld fusion attained.

Short circuit, a great process for carbon steel rotated pipe roots.

However not used for decades due to process ignorance

weld shop myths, & misleading code information.

While the code bodies in 2013 have very little negative to say about pulsed MIG process, for those of you with grey hair, you may remember that these same codes typically either did not allow regular MIG for pipe welds, or the code weld specifications made incorrect recommendations or negative comments on the use of the MIG process. For example, for five decades, the MIG short circuit process was treated like a leper, yet the weld reality was and still is in 2014, the Short Circuit mode is one of the best available weld transfer modes for rotated, open root, carbon steel pipe welds. Most of the pipe shops which were embedded with the SMAW and TIG process would typically not consider using the MIG spray transfer mode for rotated pipe welds, yet the reality has been that MIG spray transfer when used correctly on rotated pipe groove welds, should provide superior weld fusion and less porosity than pulsed MIG or SMAW .

THE WELD QUALITY CONSEQUENCES OF PULSED MIG WELD ENERGY TO WELD MASS AND WELD SPEED:

What most weld decision makers and QA personnel are not aware, is that there is on most all position, pulsed MIG pipe weld applications thicker than 6mm, a poor ratio between the moderate pulsed MIG weld energy attained, (influenced by the low back ground current) and the high weld deposition rates that can typically result with any pulsed MIG pipe welds. The healthy pulsed MIG weld deposition rates push the weld speeds, and faster weld speeds often don't allow the time required for the desired weld fusion. Also the larger the weld mass the more of the weld energy is required for the weld and therefore less weld energy can be applied to the weld fusion.

For those of you moving aggressively forward with the manual pulsed MIG process for your all position manual pipe welds, do not be surprised even when using the highest welder skills, that the NDT will pick up extensive lack of weld fusion in the first and second passes over the roots, especially when using sluggish stainless, or alloys wires..

It's a good job every weld produced, does not require an X-Ray.

.

YOUR LOCAL SALES REP WON'T TELL YOU THIS BECAUSE TYPICALLY THEY ARE NOT AWARE OF IT. ON APPLICATIONS > 6 mm, OPTIMUM PULSED, MANUAL MIG WELD FUSION IS OFTEN MARGINAL OR INDICATES LACK OF FUSION. PULSED MIG IS ALSO IS A PROCESS THAT IS HIGHLY SENSITIVE TO THE EQUIPMENT AND HUMAN VARIABLES THAT INFLUENCE MANUAL PULSED MIG WELDS.

2005: WELD CODE STIPULATIONS NEED TO TAKE INTO CONSIDERATION THE WELD QUALITY DIFFERENCES ATTAINED BETWEEN MANUAL AND AUTOMATED PULSED MIG WELDS:

With the global weld process control apathy that prevails, I do not expect to find weld codes that discuss the mechanized versus manual pulsed weld differences and the weld quality consequences of those differences. When a code body puts it's stamp of approval on a weld process such as Pulsed MIG, the code is sending the message that this is process that's also acceptable for both manual and mechanized pipe welds.

With automated pulsed MIG pipe line welds in which the use of multi-MIG guns is typical, electronic MIG power source features such as volt or current energy spikes can be applied to the weld weave dwell times. These controlled, increased weld energy spikes will improve the 5G pipe side wall weld fusion. Also the controlled pulsed MIG weld speed, the controlled, mechanized weld weaves and the constant wire stick out. are the automated features that will have a lot to do with success of the mechanized pulsed MIG process when used for pipe line welds. Take away these important controls and as it's been for three plus decades the manual pulsed MIG process has proven that the attainment of 100% X-Ray all position pipe weld quality is a challenge. By the way this is a challenge that weld shops in 2013 do not have to face when they can use the far superior TiP TiG manual or automated weld process.

API. 5.2.2 Short Circuiting Gas Metal Arc Welding (GMAW-S). The use of GMAW-S shall be limited to the following conditions:

[] For vertical welds, the root pass and second pass progression for a material of any thickness may be either uphill or downhill.

Ed's response. There is no logic in using MIG short circuit, with the vertical up position on any weld application. Just as there is no logic in this cold process being used for the second pass which from a weld fusion potential is the most sensitive part of any pipe weld..

[] The fill and cap pass for butt or fillet welds may be welded with the short circuit process, provided the thickness of any member does not exceed 3/8 in. (9.5 mm) and vertical welding is performed with uphill progression.

Ed's response. Watch out for lack of weld fusion with the short circuit process welding vert up on any steel parts > 1/8 (> 3 mm).

.

Note: Thanks to the many changes that occurred over the two decades of pulsed MIG equipment evolution, at this 15 year old site, you may note that time frames will often precede my comments.

< 2006. Numerous global weld shops purchased pulsed MIG equipment before 2006. When promoting pulsed equipment for welding steels, the marketing and sales personnel who manufactured and sold the costly pulsed equipment may have told the weld shops, that with the pulsed MIG equipment purchase the weld shop will not have to worry about:

[a] poor arc starts,

[b] weld spatter,

[c] smoke,

[d] weld inconsistency.

[e] the weld quality.It's one thing for sales or equipment reps to promote real world weld benefits about a weld process or consumable, it's another thing to promote greatly stretch the truth to an already confused weld industry.

"ARC STARTS". Take any well made, traditional CV power source manufactured since the nineteen sixties. With this power source you should have the ability while manually welding to produce "100 arc starts" without one arc start issue. Those golden oldie power sources will provide consistent arc starts as long as correct weld data is applied.

MIG arc start issues in many "robot cells" are not typically caused by that USA or Japanese manufactured MIG power source. Most of the robot arc start issues are simply a result of people induced, poor robot weld start and weld end data. If you want to cut down on robot down time, my robot MIG Process Control book and training CDs provide the unique data required for optimum robot arc starts.

Weld Reality. "Weld spatter". If spray or short circuit weld transfer is set with "correct weld data", the weld spatter that will occur on most applications will be minuscule and should not have cost consequences for most weld applications.

Weld Reality. "Weld smoke". The weld smoke from carbon steel welds and traditional MIG spray transfer welds with optimum argon mixes that contain 10 to 20% CO2 is minimal, especially if the weld voltage is set for the shortest arc lengths. In over three decades of testing MIG smoke that occurs with carbon steel welds and argon mixes, the smoke has never been proven to be a health issue. Also lets face it, some of the largest complaints about weld smoke come from union shops in which the majority of robot and manual cells have an exhaust system installed.

Weld Reality. "Weld consistency". On the subject of weld consistency and steel welds. In forty plus years of MIG welding using good CV equipment, I have never made a weld that was negatively influenced by the so called inconsistency of the CV MIG power source. In contrast, with with the majority of pulsed equipment built before 2006, to attain your most consistent weld results, you simply switched the pulsed mode "off".

Visit my MIG equipment evaluations to see pulsed

equipment and real world arc consistency issues..

.

Weld shop attitudes are mostly influenced

by those in the front office.

.

IT''S EASY TO UNDERSTAND THAT THE MANAGERS, ENGINEERS OR SUPERVISORS WHO LACK PROCESS CONTROL CONFIDENCE, WILL BE RELUCTANT TO PROMOTE COST EFFECTIVE PROCESS, EQUIPMENT OR CONSUMABLE CHANGES:

Irrespective of the weld equipment utilized, the biggest deterrent to weld optimization through weld change is often apathetic, process manufacturing and engineering management who may be provided with cost effective, TOUCH IT, FEEL IT, SEE IT solutions to their weld manufacturing issues, and yet they simply lack the manufacturing balls and process confidence to make the changes that are required on the weld shop floors..

2008. MIG EQUIPMENT AND WELD COST JUSTIFICATION: After MIG welding now for five decades, I believe all you need for optimum welds on the majority of all carbon steels, low alloy steels and stainless applications is a traditional, low cost, durable, easy to repair CV MIG power source like this approx. $3.200, Miller, CP302 MIG power source and wire feed package. Similar CV packages are available from ESAB and Lincoln.

.

2008: WELD TECHNOLOGY VERSUS REAL WORLD WELD BENEFITS: When you examine the pulsed MIG electronic technology required to create one weld drop per pulse, it's impressive. When you examined the weld application benefits derived from the single drop per-pulse process on carbon or low alloy steels, the practical and measurable weld benefits are typically minuscule or often the figment of a weld equipment salesman or marketing managers imagination.

2008: PULSED EQUIPMENT SELECTION AND TRADITIONAL WELD MODES. The weld shops ability to provide a logical, unbiased weld process application comparison of the pulsed mode benefits and disadvantages, against the benefits and disadvantages of the traditional MIG short circuit, globular and spray transfer modes, is what should make the selection of pulsed equipment either a success or failure for many welding shops. That expertise is available in my process control - best practice, self teaching - training programs,.

.

|

WELD PERSONNEL WHO LACK WELD PROCESS CONTROL EXPERTISE AND THEN TRY TO EVALUATE A WELD PROCESS, WELD EQUIPMENT OR CONSUMABLES, USUALLY END GETTING ADVICE FROM A SALESMAN, AND THAT TYPICALLY LEADS TO UNNECESSARY WELD SHOP COST CONSEQUENCES..

It's easy to sell unnecessary costly equipment and consumables

to a manager that knows little about the process.

If someone in a weld shop believes they need Wave Forms to make

optimum MIG welds, they likely should be working in a Donut shop.

There is a common problem that occurs daily in the global weld industry, and that involves the general management confusion with weld skills - experience and weld process control expertise. Most manufacturing companies employ MIG welding individuals that have many years of weld shop experience and may have extensive welding skills, however few companies employ weld shop personnel that have the in-depth MIG weld process - best weld practice expertise that's necessary to consistently optimize MIG (and FCA) welds and evaluate MIG equipment, weld transfer modes and consumables.

Managers: If you have employees in the weld shop that "play around" with their MIG or flux cored weld controls, how can you expect these persons to provide a qualified evaluation of new MIG welding equipment or weld consumables?.

.

.

Average USA yearly manual welder wage, $50K. Average cost of a complete Robot cell cost $50 - 150K. Average cost of a pulsed MIG power source $8K to 15K.

MIG Process Controls - Best Practice Training Resource, "Priceless" for a few dollars.

WHY DO MANY COMPANIES STARVE THEMSELVES FROM HIGHLY

COST EFFECTIVE PROCESS CONTROL TRAINING RESOURCES?

.

It never ceases to amaze me when someone calls me about a MIG or flux cored weld issue that's costing their company thousands of dollars and that person states the manager of the shop is reluctant to spend a few hundred dollars on my weld process control - best practice training programs that would prevent the weld problems from occurring.

Next time you go into the weld supervisors or managers office, look to their shelves for any books or training resources on Robot or Manual MIG - FCAW "Weld Process Controls - Best Weld Practices". You typically won't find any as, they are still here in my office waiting to be shipped out..

<2006: As the MIG equipment becomes more electronically sophisticated, the weld shop has one more thing to worry about, the weld equipment reliability and durability.

It's an ironic fact, that today in many weld shops that use pulsed equipment, the shop manager or maintenance supervisor may think the pulsed equipment is doing great, that is if it only breaks down once a year, or it manages to lasts through it's 36 month warranty. Someone should remind the manager that in contrast, the traditional, much lower cost, CV MIG power source, should typically last on the weld shop floor for at least 10 - 15 years before Fred the maintenance electrician has to take a look inside it.

Note: Before they purchase that pulsed MIG equipment, few weld shops would be aware that the typical repair costs on a pulsed MIG power source could easily cost more than the purchase of a brand new MIG power source and wire feeder.

FEW MANAGERS CAN JUSTIFY WHY THEY WANT TO PUT COSTLY, SENSITIVE ELECTRONIC WELD EQUIPMENT IN A WELD SHOP ENVIROMENT.

It's not just the unnecessary pulsed MIG equipment complexity and high equipment price that should be an issue at many plants, the less durable pulsed equipment brings it's own concerns. After more than two decades of MIG pulsed equipment product development, some pulsed weld equipment manufactures are proud of the fact that they offer a warranty for 36 months.

FEW INDIVIDUALS IN THE WELD INDUSTRY HAVE THE SKILLS NECESSARY TO MAKE REPAIRS TO PULSED MIG EQUIPMENT, AND FEW HAVE THE PROCESS CONTROL EXPERTISE NECESSARY TO JUSTIFY WHY THEY SHOULD PURCHASE THE PULSED MIG EQUIPMENT FOR THE COMMON CARBON STEELS AND LOW ALLOY WELDS.

With the simple to operate two control CV MIG equipment you don't want to waste time asking MIG - FCAW process questions in the weld shop . For example if you asked 10 welders for more MIG weld heat, likely 5 of them would turn up the weld voltage and the other 5 would adjust their wire feed control. And certainly you would not want to ask where Spray Transfer starts on the wire feed control with that 1.2mm steel wire.

If the simple two control MIG weld parameters used with regular, CV, MIG welds are poorly understood, why would the weld shop management want these guys, without process training, to then adjust the complex pulsed MIG parameters. As mentioned previously, with the Pulsed MIG mode, the welders have more than wire feed rates and weld voltage to be concerned with. A slight change in the pulsed MIG peak, the pulsed background current, the pulsed frequency, the pulsed width, the pulsed Hz, the pulsed wave forms, the wire stick out or the the pulsed weld current, may or may not produce the weld results required.

INSTEAD OF PROVIDING THE NECESSARY MIG - FLUX CORED WELD PROCESS CONTROL TRAINING, AND STRIVING TO KEEP THINGS SIMPLE IN THE SHOP, TOO OFTEN WELD MANAGEMENT CREATES A WORK ENVIROMENT WHICH ENSURES THEIR WELD PERSONNEL WILL PLAY AROUND WITH THE WELD CONTROLS.

Pulsed MIG equipment mfgs state, "use our preset weld schedules". Remember, just as the ever changing mill scale can dramatically affect the weld fusion, also a minor change to any of the primary pulsed parameters can also have a dramatic impact on the weld fusion and weld quality attained. The pulsed MIG power source may provide their own unique, built in weld schedules, however these programs will not take into account the many variables that can effect the welds. Also please note that you can almost guarantee that each weld schedule on the different or newer pulsed equipment will typically provide a different way to weld those common simple simple gage to 1/4 steel welds.

.

2008: Each year, pulsed equipment manufacturers will continually strive to make their top end weld equipment "electronically unique" with the addition of more and more unnecessary bells and whistles and built in weld schedules. The weld reality is this. What applies to one pulsed MIG power source will typically not apply to another. The standard, simple, universal, two parameter CV short circuit and spray transfer weld procedures which have been practical, logical and effective weld tools for more than five decades, are slowly becoming meaningless as the heavily marketed pulsed MIG process takes root.

..

While essential weld variables should always be a concern with code quality welds, the common essential weld variables found in auto - truck plants will typically have little meaning where the mfg management will lack weld process controls and best weld practices expertise. In most plants in the auto industry you will find that;

[] best robot weld practices are none existent,

[] robot weld process controls have no meaning,

[] part design tolerances are little more than joke,

[] part cleanliness has little meaning,

[] welding on galvanized coatings is the norm,

[] weld process control training is none existent,

[] MIG equipment always being utilized weld personnel who don't know how to optimize it.

.

.

|

.

2008. The global truck manufacturers and their tier suppliers annually spend hundreds of millions of dollars on ISO compliance, different lean manufacturing methods and training programs, yet the weld reality is few of these companies have employed managers, supervisors or engineers who will spend a few hours in trying to understand the weld manufacturing equipment they utilize on their shop floors. It would be easier to find an honest politician than to find a plant or engineering manager who is aware of the requirements to establish MIG and flux cored Weld Best Practices and manual or robot Weld Process Controls.

.

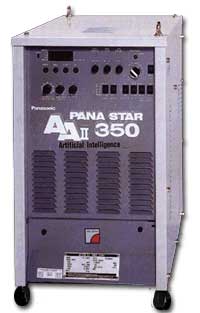

MID 1990s: THE PANASONIC PULSED ~RIPPLE ~~ STORY.

If one weld tale represents the BS that has surrounded the pulsed MIG process, it's the following Panasonic pulsed equipment story. A few years ago, a Panasonic rep approached Airgas the company I worked for. Airgas is the largest global MIG weld equipment supply company. Panasonic wanted Airgas to represent their so called, unique pulsed MIG product line for the USA - Canadian markets.

It was my job at Airgas to evaluate MIG welding equipment and select the equipment to be sold by the Airgas distributors. The Panasonic rep and his boss sat in my office, and for two hours described the wonderful feature benefits of his superior electronic pulsed MIG power source. I listened as these guys showed me their oscilloscope photographs of the power source output, and informed me how their unique MIG power source had "smoothed out the traditional pulsed power source output ripple effect" Those "ripples" I was told, occur with a regular MIG CV power source. While the Panasonic rep proudly revealed his ripples, I thought it was interesting that he did did not show a graph with the important parameters such as weld current and voltage.

During the meeting I thought. "What a fool I have been. I have been around MIG welding since 1961 and did not realize I needed ~~~"Ripple Proof Weld forms to make good MIG welds" ~~~

The Panasonic team then went over their power source, numerous electronic features. They were really impressed with the fact that their unit provided "self diagnosis" of its electronic ailments. In other words his pulsed power source would shut down if the weld output deviates from the information put in.

I told the Panasonic team to send one of their units to my companies training department in Chicago. At this location I could compare the pulsed equipment along side a regular 450 amp, CV power source from Miller. The Miller Delta Weld 450, was a MIG power source that unfortunately and unknowingly provided the "inconsistent ~~~ripple output effect~~~ . Which was unfortunate as I believed that the Delta Weld was the world's best, CV, MIG power source.

The Panasonic unit sat in the Chicago training facilities for three weeks before I could test it. The reason for the delay was the power source with it's intelligent self diagnosis feature, shut itself down on many different occasions. To add to it's misery, this pathetic Japanese power source would not restart after it's third shut down. To restart the Panasonic power source we had to bring in the MIG equipment specialist from Panasonic.

Finally after flying in half the Panasonic company, and being treated by Panasonic to many wonderful lunches in local Japanese restaurant, the red faced Panasonic personnel got their state of the art, pulsed MIG power source running. The power source was fixed, and it actually stayed on after being switched on.

Now we had a pulsed unit that actually ran, I then invited the Panasonic weld rep to demonstrate his unique pulsed equipment. As

with all MIG equipment evaluations, I provided the clean steel and stainless weld samples that were 1/16 - 1/8 - 3/16 - 1/4- 1/2, (1.6 - 3.3 - 5 - 6.4 -13 mm). This steel thickness range represents the majority of North America's bread and butter MIG welding applications.

The Panasonic pulsed weld package presented at that time for the weld tests sold for approximately three times the cost of a regular CV, MIG power source. The Panasonic weld team and their unique power source team went head to head with myself and my trusty Miller Delta-Weld 450. As Paul Harvey used to state on his radio show, "well now for the rest of the story".

On every test weld I made, the much less costly, much more durable Delta-Weld was easier and quicker to set. I typically would have the test welds finished before the Panasonic team had set their weld parameters. From a weld quality and productivity perspective the Delta Weld easily again out performed the Panasonic. After all the welds were complete, the Panasonic reps spluttered a few Midwest words I usually only hear in welding shops, and left looking for another ~~~North America Sucker to sell their ripple story to ~~~.... Note: They found many.

Mid 1990s. The Panasonic Chicago test was my first introduction in the USA to a Japanese MIG pulsed power source, and my first introduction to the appalling lack of Japanese MIG weld process expertise that was indicated in their so called weld process experts. .Late 1990s. As the Panasonic power source manufacturer still touts that their pulsed MIG product represents one of the most sophisticated electronic state of the art pulsed MIG power sources sold in the USA, I thought I would spend some time seeing what the 1999 pulsed Panasonic HM 500 power source had to offer. The 19999 AWS weld show provided the opportunity. The following is not word for word but it is does represent the fundamental content of my conversation with the Panasonic reps at the weld show.

.

The Panasonic ~~~ Pulsed MIG ~~~ Saga Continues.

At the 1999 AWS show, I asked the Panasonic rep to describe his new HM 500 pulsed power source. The conversation that followed was quite interesting.

The young Panasonic rep at the weld show who did not know me said:

"Ed, our new, Dip. (what happened to Ripple?) pulsed MIG power source is really unique, as it provides "Artificial Intelligence" with many other electronic benefits. This power source is constantly analyzing the arc output weld data and makes parameter corrections for the arc. This power source provides superior penetration to any other pulsed power source..

The Panasonic sales rep continues.

"Ed, you may not be aware that after the Kobe earth quake in Japan, weld penetration became a prime issue (I guess in Japan weld penetration was not a concern before the earth quake) . He continued, "one of the things that effects pulsed weld penetration is when the pulsed arc length changes. If the pulsed arc length, (the distance between the wire tip and weld) is shortened, the pulsed weld drop is not allowed to form without interruption, This weld drop interruption and weld transfer inconsistency can effect the consistency of the weld fusion attained.

At this stage of the one way weld conversation from the Panasonic rep, who by the way, looked like he had just graduated from high school, I have to admit that this kid's weld comments had left me speechless, which for me as you should be aware when its comes to the subject of welding, is really unusual.

What this Panasonic child was not aware, for the last three decades, over five decades, in thirteen countries, I have set thousands of different manual and robot MIG weld applications always with a focus on attaining optimum spatter free welds, with the best possible weld fusion, and always at the maximum possible weld deposition rates. The MIG welds I produced could pass any code weld specifications, and were all carried out with traditional, durable, low cost CV MIG equipment.

It's a pity it took an earthquake in Japan before some Japanese weld equipment manufacturer became concerned about lack of weld fusion, which by the way is a primary common defect from the Pulsed MIG process..

An ironic weld point. If the Panasonic equipment and the MIG and flux cored process had been used for structural steel applications used in seismic locations, in contrast to traditional CV equipment and argon mixes, there is no doubt in my mind that the Panasonic equipment would produce inferior weld quality with extensive lack of weld fusion issues.

.

.

When any weld salesmen, starts to talk in a language unfamiliar to you,

take three steps back, say good buy to the BS and get on with your life.

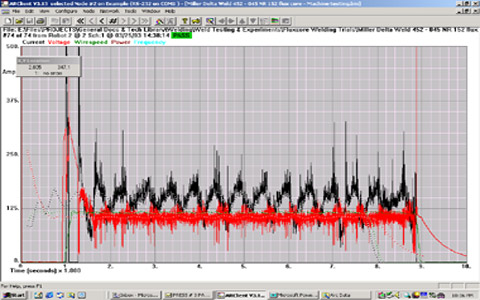

This was an oscilloscope Volt / Amp reading of a Panasonic Power source

taken shortly after the Big Ripple and "Constant Weld Fusion" discussion.

Volts Red. Weld Current Black.

.

| The following is an oscilloscope of weld voltage and current from a traditional CV power source that cost 200% less than the above Panasonic power source with it's magic ripples and waves. |

Volts Red Current Black.

PERHAPS THE PANASONIC PERSONNEL SHOULD HAVE BEEN EDUCATED AS TO WHY THE REGULAR MIG PROCESS WITH SPRAY AND SHORT CIRCUIT TRANSFER, HAS BEEN SO EFFECTIVE FOR 50 YEARS..

The regular, low cost, MIG power source, provides that unique constant voltage (CV) attribute, in which the MIG power source has always instantly made it's own weld current correction for a wire stick-out variation.

With CV MIG equipment, weld voltage and current variations should be miniscule, especially during a robot weld in which the wire stick out variations should be always be minimal. With MIG all welds, even a novice weld person should understand the importance of stable weld current and voltage.

It's easy to produce the perfect fillet.

.

It's interesting to note that the Panasonic rep placed concern on the negative attributes of a short arc length with the pulsed process and the negative impact on the weld fusion potential. In contrast, the regular MIG spray mode plasma and it's weld stream is much less sensitive to arc length variations and this MIG arc does not require low back ground current and therefore provides more consistent weld fusion.

I did not get into the regular MIG versus Pulsed MIG discussion with the Panasonic rep, it would have been time wasted. To try and rectify brain washing or process ignorance takes extensive time, and I only had one hour with this guy. In my mind, I instead gave him a pat on his head and sent him back to his Japanese master.

[] Japan is a country that for decades used straight CO2 for most of it's globular, spatter covered MIG welds.

[] Japan is a country that lacked gas plants that could make argon mixes to enable controlled spray transfer.

[] Japan is a country that for decades lacked knowledge about MIG Spray Transfer mode that comes with using argon mixed gases.

At the same show, I asked another Panasonic rep a simple question about the "pulsed wire feed range potential". I said, "can your intelligent power source provide a practical measurable benefit like extending the traditional MIG spray wire feed range so that robots can weld faster? The Panasonic rep instantly developed my wife's weld glazed blank look. He replied finally with an answer that made sense. He stated "he was not qualified to answer", and he handed me over to his technician.The Panasonic technician was ready to demonstrate his latest Panasonic Power source with an 0.052 (1.4 mm) carbon steel wire. I asked that the weld wire be set at a common, "high spray transfer" setting of 420 in./min. This setting would be used to weld a 6 - 8 mm fillet welds on > 9 mm plate. As I expected, at the wire feed rate of 420 in./min, the pulsed plasma was highly agitated and digging. The pulsed plasma was simply unsuited for a controlled weld. I of course wondered how it was possible that the Panasonic reps and technicians were "qualified to discuss the

influence of highly complex, artificial intelligence" on the MIG arcs weld characteristics, yet they did not know a simple limitation on the MIG pulsed wire feed range capability.

For five decades, Japan with no argon mixes had MIG welded with straight CO2 and the resulting erratic, globular weld transfer, daily created a welding mess. In the nineteen nineties, Japanese companies like Panasonic went from boom boxes and TV manufacturing to try to make sophisticated welding equipment. The Japanese made poor, erratic, pulsed MIG equipment which they attached it to their robots and brought this package to the USA, a country that for more than five decades had provided most of the world's best MIG equipment.

When it came to MIG welds, Asian auto giants like Toyota and Honda employed engineers that experienced welding the Japanese way which was first you MIG weld then you grind, with typically more grinding than welding. Panasonic a prime supplier to these companies came to America with electronic MIG equipment that could barely function, equipment that provided zero weld benefits and created numerous weld and robot issues. How did America respond to the Japanese weld equipment? The apathetic North American manufacturing management, led by auto / truck industry weld decision makers, (an industry also notorious for it's bad welds) opened the door, and said if it's Japanese it must be good, so come on in..

Nov. 2007: THE PULSED ACHILLES HEEL: Even with the world's best pulsed equipment, when welding many common applications, the Pulsed MIG process will always have it's Achilles Heel. This web site is the only place in the industrial world where you will read the following negative point on pulsed MIG welding. Please note the copy right symbols are in place for a reason.

With the formation of each pulsed MIG weld drop, the fluctuating pulsed MIG arc plasma,

goes from a "narrow to wide plasma profile". The pulsed MIG plasma changes are of course influenced by the back ground to peak current changes. With the low back ground current, for a micro second you have much less ionization taking place in the plasma zone.

In contrast. The traditional spray transfer, will provide a more constant, cone shaped, plasma profile. Improving the ionization stability and maintaining the surface area of a MIG arc plasma enables the following;

[] More consistent electron transfer from the negative weld surface to the positive wire tip. Useful in improving arc stability especially in automated high weld speed applications and also in maintaining consistent weld fusion.

[] Improving the density and coverage of an arc plasma improves oxide surface removal. Also adds to arc stability. Beneficial on mill scale / coated applications and on those single pass welds larger that 7 mm.[] A consistent, denser wide plasma also provides wider distribution of weld heat.

Improves weld fusion profiles, especially over the length of the side wall weld fusion on fillet welds.

Of course pulsed works well on many applications yet anyone who has used the process on a wide range of applications is aware that it's a process that can cause issues on many welds. When you add the pulsed arc instability that is common from many pulsed power sources, with the fluctuating pulsed plasma, you can understand why in two decades I went into hundreds of companies around the globe and switched the pulsed mode off and changed the arc back to spray. Changing wave forms does not change the Achilles Heel.

I hope your company does not make inconel or stainless

pulsed MIG clad welds that look like this.

Above. Some USA power station, boiler water wall mechanical strength and longevity being destroyed by poor manual Pulsed MIG clad weld practices and equipment. And of course the real reason is the poor weld management that likes to take $20 - $30lb, weld consumables and then throw the chrome and money out of the window.

Above Clad Photo proudly displayed in a weld magazine:

This sad approach to placing manual clad welds on boiler water wall tubes, was proudly displayed on the cover of a 2008 USA welding magazine. The magazine clad article was about the wonderful, new, 2008 pulsed MIG equipment available from Miller Electric and the suitability of this equipment to this Inconel clad application. The clad welds in the photo reveal a poor pulsed MIG transfer weld characteristics, a poor pulsed MIG program, poor clad weld practices and poor weld techniques. These narrow, clad welds will create inconsistent, unnecessary weld over lap, poor and excess weld tie ins, inconsistent clad dilution, excess start stops, and also there will be extensive lack of clad weld fusion. This clad weld operation will dramatically negatively effect the boiler walls by producing excess distortion, uneven wear, unnecessary stress risers, issues that will reduce the boiler operation efficiency and longevity.

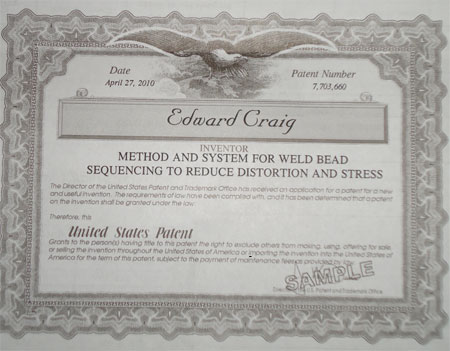

Ed's USA / European patented MIG weld process control approach to boiler water wall clad weld. These welds were made with a $5000 (2005) pulsed power source.

2006: Inconel 622 on Boiler Water Walls.

An untouched weld section take from 300 sq/ft clad section.

Ed's contribution to the Power and Waste Management Industries.

2006: Welding Services (WSI) now Aquilex Atlanta: WSI is primarily involved in repairs and refurbishment in the power, waste energy and nuclear industries. In terms of water wall clad

welding, WSI has clad approx. 80% of the North American boilers. Each year WSI uses approx.

one million pounds of Inconel 625-622 and 300 series stainless MIG wires for cladding boiler

water wall tubes.

2006: ED WAS REQUESTED TO DEVELOP A NEW WATER WALL CLAD PATENT:

While WSI has produced some of the most innovative, automatic MIG cladding equipment available in North America, WSI did not have a resident MIG process control expert who had the expertise necessary to make radical improvements to it's water wall clad MIG welds.

Ed was contracted for this work by the WSI engineering manager. In less than 6 months, as the following pictures indicate, Ed dramatically improved the water wall overlay weld quality and a new USA and European clad weld patent was developed.

WITH ALL CLAD WELDS, THE MOST DESIRABLE CLAD WELD ATTRIBUTE IS ACHIEVE THE LEAST POSSIBLE WELD LESS DILUTION:

IMPROVING WATER WALL BOILER LIFE & OPERATING EFFICIENCY:

As many in the power industry are aware, with any water wall clad weld application "less is always better". With less clad weld shrinkage and less clad weld defects, the boiler water walls will operate more efficiently when the single pass clad weld surface is as thin as possible and when the clad weld pass thickness is both uniform and free of weld defects.

The traditional methods of both manual and automated clad welds on boilers would produce clad welds that too often had too much weld filler, lacked uniformity, had poor weld tie ins and had extensive lack of fusio. The Inconel clad filler metals typically can cost over $23 - $26 LB. With these costly weld wires, it makes no sense to produce excess weld and create excess stresses and deformation on the boiler walls. My new clad patent dramatically improved the single pass clad weld quality and dramatically reduced the typical single pass clad weld thickness providing extensive clad cost savings from the reduced weld wire requirements:

DRAMATIC REDUCTION IN CONSUMABLE WELD COSTS PER-OPERATION.

With Inconel clad wires at $23 - $26LB and large water wall areas to be clad, the clad weld consumable costs are typically a large part of the cost of a boiler clad application costs. My new pulsed MIG procedures reduced the amount of clad single pass, clad weld overlay by approx. 28%.

WITH SINGLE PASS CLAD WELDS, YOU HAVE UNIQUE WELD REQUIREMENTS FOR THE CLAD WELD SURFACE TIE-INS AND FOR THE CLAD TO TUBE WHICH REQUIRES MINIMUM CLAD WELD DILUTION:

With water wall clad applications, the minimum, "single pass" Inconel weld clad chemistry required is 20% chrome. As the filler metal typically provides approx 21% chrome To attain the minimum chrome requirements, the pulsed MIG weld procedures with the vertical down clad welds consistently attained minimum weld dilution < 8%, while achieving consistent weld fusion on the carbon steel boiler tubes.

BOILER SHUT DOWN IS COSTLY AND WELD TIME IS VERY IMPORTANT WHEN CLADDING LARGE WATER WALL AREAS THAT SOMETIMES REQUIRE OVER 1000 sq/ft OF CLADDING. TO SPEED UP THE OPERATION, THE CLAD PROCESS NEEDS TO PRODUCE THE HIGHEST POSSIBLE WELD DEPOSITION RATES:

The primary part of clad weld costs on large weld areas as found with most clad boiler wall applications, is dictated by the MIG weld deposition rates attained. Ed's new patented clad procedure with the unique, WSI automated weld equipment, enabled a single operator controlling two guns to deposit approx. 30 lbs/hr.

Weld spatter with any MIG weld mode is an indication of

LACK OF MIG WELD PROCESS CONTROL EXPERTISE.

2006: Ed's patented pulsed MIG weld gun on the left providing 15 - 16 lb/hr. Note the absense of weld spatter at a time period when the pulsed technology was still not quite there. Normal water wall pulsed MIG clad welds on the right:

Unless you sell those costly clad weld consumables,

with clad boiler welds, less is better.

Eds single pass welds provided dilution so low the chrome was > 20%

BELOW PULSED MIG CLAD WELD WITHOUT WELD PROCESS CONTROL EXPERTISE: Before Ed. now Em got involved with boiler water wall welds. The picture below was considered by Welding Services (Aquilex) Atlanta to be an optimum for cladding on boiler water walls. The clad welds were either stainless or Inconel 622, wires. Weld position, vertical down..

PULSED WELD CONTROL EXPERTISE. Below, Ed's untouched the new water wall clad welds.

The weld quality and cost savings were so unique and extensive that WSI patented Ed's process.

ED DEVELOPED A UNIQUE GAS MIX FOR THE INCONEL CLAD WELDS.

Those vertical down 622 Inconel / stainless CLAD MIG welds in Ed's patent were derived from a low cost, five thousand dollar, pulsed MIG power source and a unique Inconel MIG gas mix that was also developed by Ed. (See the MIG gas data section at this site).

Note: This patent would not have been possible without the Aquliex, (WSI), customized. automated MIG weld equipment that compensated for the wire stick out and arc length variations that resulted from the water wall curves.

After a few months of pulsed MIG weld process development. The final Inconel 622, single pass, clad weld results were developed by Ed for WSI..

Note the smooth single layer MIG clad surface with optimum weld ties ins. This clad application was delivered from a low cost, $5000 pulsed MIG power source in 2006. This pulsed MIG clad weld has a smooth finish similar to a $250.000 laser - powder clad overlay.

In contrast to the conventional water wall clad MIG welds, in contrast to what WSI was producing, Ed's pulsed MIG process change required 28 % less weld metal per sq/ft of coverage. These single pass, low dilution welds provided > 20 % chrome.

In 2010 an International - USA patent on cladding was presented to Ed and WSI.

Follow up eight years later in 2014:

From Ankit Jindal, Welding engineer, M/s ISGEC HEAVY ENGINEERING LTD, INDIA.Ed, I just viewed the pictures of your pulsed MIG cladding technique with inconel 625 over carbon steel water wall tubes. My company is a major boiler manufacturer here in india and we have installed more than 550 power boilers in more than 30 countries.

We will be working on a project where we will be cladding INCONEL 625 over water wall panel tubes. Initially we thought of doing it with manual pulsed arc MIG, vertical down by hand, but after viewing your superb finish and minimum dilution method, I couldn’t resist to write it to you. We are very much impressed with your MIG process control expertise and your pioneer knowledge of the subject.?We will be very much grateful, if you’ll be able to spare a some time to chat with us.

More info on clad welds by Ed...

"The welds produced should always

be mightier than the weld sales reps word"

.

|

.

.

.

.<2004. I was really surprised at a visit to a large manufacturing plant in the middle of the corn fields of the mid west, to find that the plant had purchased a large number of Panasonic, pulsed welding machines to weld carbon steel, farm and related equipment.

I mention the mid west, because in this part of the US, you will typically find a few hard working, workers like welders and supervisors who weld during the grave yard shift, then take care of their small farms during the day.You might ask, how is it that practical, rational Mid West people could get sucked into purchasing costly, Japanese Panasonic weld equipment loaded with useless bells. The MIG equipment was being utilized on common thin gage to 1/2 (12mm) carbon steel farm equipment applications? These applications have been successfully MIG welded by Deere, Massey Ferguson, Caterpillar and Harvester for the last 50 years using less costly, easy to operate, more durable North American MIG welding equipment.

Cost effective, greater productivity, practical, logical, easy to use, good durability and no bull shit, these are the words that people in the mid west used to like to hear.

These were not the words used when a John Deere weld engineer made what I think was an illogical, stupid and costly weld process decision. In the nineteen nineties this engineer converted his organization over to over priced, poor performing, low durability pulsed MIG equipment. Can you remember in the nineties how unstable computers were? well pulsed MIG equipment was much worse. To add insult to mid west logic, the weld engineer made the MIG equipment conversion based not on weld productivity or quality performance, he made it on "weld smoke reduction". I hope you are all aware that when MIG welding carbon steel applications, the weld smoke from traditional MIG with argon 10 - 20 % CO2 mixes has never been an industrial safety or work issue. I believe it would have been more logical and beneficial to his company's bottom line, if this weld decision maker had instead focused on the weld equipment and process and it's weld fusion potential, arc stability and weld deposition rate potential.

ITS COMMON TODAY TO COME ACROSS SO CALLED TECHNICAL PEOPLE WHO CAN'T SPEND MORE THAN FIVE MINUTES ON A SUBJECT, AND WHEN THESE GUYS NEED TECHNICAL ADVICE, THEY DO NOT THINK TWICE ABOUT ASKING A SALESMAN..

2008: Is it possible that this computer driven, we have to have it now generation of weld shop decision makers is so enamored by electronics that they have forgotten the purpose of a weld

In many of the weld shops I deal with, I will often meet robot weld technicians, many of them just out of high school. Many, (not all) of these young guys will have spent five minutes reading a Lincoln or Miller glossy sales brochure on a new artificial MIG power source, and bingo they become weld experts. You have met these guys, these are the new weld experts that would much rather give you their highly qualified opinion on the welds, rather then spend five minutes listening to some one who was controlling MIG welds a decade before they were born..

Ninety Pre programmed Pulsed Weld Schedules. You Have to be Nuts.

A MIG pulsed equipment benefit often touted by MIG equipment manufacturers and their sales force, is that their unique pulsed power source offers up to ninety weld schedules.

After forty years of making MIG equipment, the MIG equipment manufacturers are now proud to provide their weld customers with sophisticated pulsed MIG equipment that enables the weld decision maker a choice of up to "NINETY Pre programmed Weld Schedules". What an incredible technology breakthrough, especially when you consider that ninety nine percent of all global MIG welds will require only "three feed and voltage settings"..

The Miller & Airco Pulsed MIG Fiasco.To be fair, it's not just the Japanese pulsed equipment manufacturers that stretched the MIG welding truth, for god's sake, you would never want to place a bible in front of Lincoln or Miller corporate personnel and ask them to tell the truth and nothing but the whole truth on their pulsed MIG equipment issues. It's also fair to state that in the mid eighties if you had purchased a US made Airco pulsed power source, (a company that once had pride in its MIG equipment performance) you would have got more from your money if you had placed the money in a paper bag and burnt it.

1980s early 1990s. A common problem that occurred with the Airco pulsed equipment, was apart from the fact that the pulsed mode was simply useless, also the printed circuit board that controlled the pulsed parameters would frequently malfunction.

In many cases the Airco pulsed circuit board failures would occur not long after the power source was delivered or even during the delivery. Many weld shops who had purchased the Airco pulsed power source, would use the pulsed equipment for years without being aware that the pulsed control boards were shot. The actual pulsed weld transfer mode that resulted from the faulty boards produced an erratic globular / spray transfer. A condition that many of the weld shops believed was normal pulsed. Of course Airco never informed the customers about the board problem.

Its another sad reflection of an industry who uses MIG equipment, to find that there are few welding personnel who can look at a weld transfer and know the difference between globular, spray, short circuit and pulsed transfer.