|

|

Welcome to the world's largest web site on MIG , Flux Cored and TIG. Weld Process Controls & Best Weld Practices. To get to the root cause of GMAW (MIG) & Flux Cored (FCAW) weld issues, requires Weld Process Control - Best Practice Expertise, & lots of Weld Reality. The site provides the MIG - Flux Cored and TIG weld information and data required to attain the highest possible manual and robot weld quality, always at the lowest possible weld costs.

This web site was first established in 1997 by Ed Craig. Contact Ed. ecraig@weldreality.com

WELDING FUMES AND SAFETY INFORMATION.

Safe practices for welding are covered in ANSI 49.1:2005"

Saftey in Welding Cutting and Allied Processes" as well as in other standards.

The most common cause of fires in mfg. facilities, a welder.

Common sense is not something you get with a good education.

How often has stupidity, poor work judgement, lack of management, greed or lack of training been the cause of serious work accidents.

Weld fume danger ignorance has gone on for decades throughout the global weld industry, however the appropriate weld fume research and safety regulations are found in organizations such as OSHA - NIOSH - AWS.

Its a sad statement that many managers will turn a blind eye to the dangers that come from fumes when welding alloys and coated parts. Of course there always has been helath consequences which can come in the short term or over long periods of time. Unfortunately its not just industry that will often ignore the dangers, the medical profession is aslo in many instances ignorant to the health hazards from weld fumes.

STAINLESS WELD FUMES

& NIOSH AND HEXAVELENT CHROMIUM:

"Hexavalent Chromium" A primary concern when welding common stainless alloys is "Hexavalent Chromium" (Cr(VI)) compounds. These compounds are part of a group of chemical substances that contain the metallic element chromium in its positive - 6 valence (hexavalent) state. Occupational exposures to Cr(VI) compounds occur during the production of stainless steels, chromate chemicals, and chromate pigments. Cr(VI) exposures also occur during other work activities such as stainless steel welding (possibly also from stainless grinding), thermal cutting, chrome plating, painting, and coating processes.

NIOSH considers all Cr(VI) compounds to be potential occupational carcinogens. An increased risk of lung cancer has been demonstrated in workers exposed to Cr(VI) compounds. Other adverse health effects associated with Cr(VI) exposure include;

[]dermal irritation,

[] skin ulceration,

[] allergic contact dermatitis,

[] occupational asthma,

[] nasal irritation and ulceration,

[] perforated nasal septa,

[] rhinitis,

[] nosebleed,

[] respiratory irritation,

[] nasal cancer,

[] sinus cancer,

[] eye irritation and damage,

[] perforated eardrums,

[] kidney damage,

[] liver damage,

[] pulmonary congestion and edema,

[] epigastric pain,

[] erosion and discoloration of the teeth.

Cr(VI) compounds vary in solubility from those that are readily soluble to those which are practically insoluble in water. In 1975 NIOSH documented the carcinogenic effects of water-insoluble Cr(VI) compounds. The NIOSH 1988 testimony to OSHA on the air contaminants standard recommended that all Cr(VI) compounds, regardless of their degree of solubility in water, be considered occupational carcinogens. NIOSH is currently reviewing and evaluating the available information on Cr(VI) compounds including the toxicology, health effects, industrial hygiene, and analytical chemistry literature in order to update its 1975 criteria document on Cr(VI).

Health EffectsCalcium chromate, chromium trioxide, lead chromate, strontium chromate, and zinc chromate are known human carcinogens. An increase in incidence of lung cancer has been observed among workers in industries that produce chromate and manufacture pigments containing chromate. An increased rate of lung cancer has also been reported among producers and consumers of pigment containing chromate. One study of chromium-nickel alloy foundry workers showed a statistically significant increase in lung cancers

Cancer - Cancer - Cancer: Hexavalent chromium is considered a potential lung carcinogen. Studies of workers in the chromate production, plating, and pigment industries consistently show increased rates of lung cancer.

Hexavalent chromium and your EYES.

Direct eye contact with chromic acid or chromate dusts can cause permanent eye damage.

Hexavalent chromium and the RESPIRATORY Tract.

Hexavalent chromium can irritate the nose, throat, and lungs. Repeated or prolonged exposure can damage the mucous membranes of the nasal passages and result in ulcers. In severe cases, exposure causes perforation of the septum (the wall separating the nasal passages). Acute exposures may cause perforation of the nasal septum within a week of exposure. Occupational Dermatoses. National Institute for Occupational Safety and Health (NIOSH) (2001, April 17). Slide 39 shows an image of a nasal chrome hole.

Hexavalent chromium and SKIN Contamination.

Prolonged skin contact can result in dermatitis and skin ulcers. Some workers develop an allergic sensitization to chromium. In sensitized workers, contact with even small amounts can cause a serious skin rash. Kidney damage has been linked to high dermal exposures.Hexavalent chromium and your BODY:

Hexavalent chromium causes lung cancer in humans. Workers exposed to hexavalent chromium in workplace air had much higher rates of lung cancer than workers who were not exposed. Studies of workers in the chromate production and pigment industries consistently show increased rates of lung cancer. Studies of chrome platers also generally show increased rates.

In this facility, its obvious the management did not give a dam.

All they had to do was swith from flux cored to MIG and provide some ventilation.

TESTS FOR EXPOSURE OR MEDICAL EFFECTS FROM WELD FUMES.

There are no routine medical tests to measure the amount of hexavalent chromium that has been absorbed into the body. Excreted chromium can be measured in urine. However, this test is only useful for measuring recent exposure to stainless steel welding fumes. In most situations, air monitoring gives the best measure of worker exposure. Therefore, measuring hexavalent chromium in blood or urine is not recommended or legally required. However, we recommend that workers who are frequently exposed to hexavalent chromium or other hazardous substances receive a complete physical examination, including an occupational and medical history, at the beginning of employment. Periodic follow-up examinations are also recommended.

SOURCES OF CHROMIUM EXPOSURE.

Hexavalent chromium materials are used in many jobs, but three jobs in particular involve frequent and or heavy chromium exposure. These jobs are

[1] spraying and cladd welding anti-corrosion coatings,

[2] welding / grinding and cutting stainless steel and alloy steels with high chrome content,

[3] chrome plating.

2018 For a decade, it's been possible to procuce welds

with fumes so low they are difficult to measure.

The Tip TiG process provides the least possible weld fumes. See TIP TIG at this site.

Safety and Weld Processes.

There is only one weld process in which the stainles, duplex and nickel alloy weld fumes should not be a concern and that weld process which provides the least possible weld fumes, is a process that I and my partner Tom O' Malley bought to North America and Australia. That unique process is called

TiP TiG (www.tiptigusa.com)

[] PROCESS. SMAW (stick) stainless electrodes that provide chrome will have much of the chrome in the "hexavelent" form generated by the reaction of the chrome with the flux constituents in the electrode coating.

[] PROCESS. FLUX CORED. Gas shielded stainless flux cored wire fume rates change with shielding gas and parameters used. The more reactive the gas mix and the higher the weld parameters used, the higher the levels of chrome. Typically FCAW chrome hexavelent levels are lower than SMAW yet the chrome content of the fumes can be higher.

[] PROCESS MIG. MIG and Pulsed MIG provides lower fumes than SMAW and FCAW. Pulsed MIG will provide much higher weld fumes than TiP TiG.

[] PROCESS TIG - TIP TIG. TIG provides low weld fume content. and the TIP TIG process which welds at much faster weld speeds than regular TIG should enable TIP TIG to be used on most stainless - nickel applications without exhaust equipment.

For good electrode fume data visit https://www.metrode.com/docs/news/HSD.pdf

Studies of stainless steel welders have been inconclusive as stainless steel welders have not been studied adequately. Evaluations by the California Department of Health Services and the U.S. Environmental Protection Agency (EPA) indicate that the risk for workers is extremely high. The best estimate of the excess risk of lung cancer from exposure to hexavalent chromium compounds at California's current Permissible Exposure Limit (PEL), every working day for 40 years, is 8 cases of cancer in every 100 workers exposed. An individual worker's actual risk depends on how much hexavalent chromium is in the workplace air and how long the exposure goes on. The lower and briefer the exposure, the less the risk of lung cancer. That's why it is important to take steps to reduce worker exposure immediately.

Spraying: In spraying anti-corrosion coatings, a liquid that contains zinc chromate or lead chromate is applied to metal surfaces through a high-pressure spray gun. The spray nozzle creates a mist that can be inhaled. Spraying coatings without adequate control measures can lead to exposure more than twenty times above the legal exposure limit.

Plating: In chrome plating, metal parts are immersed in a liquid solution of chromic acid through which an electric current flows. The electroplating process creates gases that bubble to the tank surface and carry liquid particles of chromic acid solution into the air. This mist can be inhaled. Hard chrome plating, which uses a stronger electric current and a higher tank temperature than bright chrome plating, creates the most chromic acid mist. Hard chrome plating without adequate control measures can lead to exposure several times above the legal exposure limit.

Welding / Cladding: In welding, cladding, the intense heat of the arc or flame vaporizes the base metal and/or the electrode coating. This vaporized metal condenses into tiny particles called fumes. These fume particles can be inhaled. Chromium fume is created by welding or cutting on stainless steel or metals that are coated with a chromium material. With specific weld processes, welding on stainless steel without adequate control measures can lead to exposure at least several times above the legal exposure limit.

It's nice to weld in confined spaces with no weld fumes or spatter.

Where is Hexavalent Chromium Found?

USES TYPES OF HEXAVALENT CHROMIUM CHEMICALS.

Pigments for paints, inks, and plastics lead chromate (chrome yellow, chrome green, molybdenum orange), zinc chromate, barium chromate, calcium chromate, potassium dichromate, sodium chromate anti-corrosion coatings (chrome plating, spray coatings) chromic trioxide (chromic acid), zinc chromate, barium chromate, calcium chromate, sodium chromate, strontium chromate stainless steel hexavalent chromium is given off when stainless steel is cast, welded, or torch cut textile dyes ammonium dichromate, potassium chromate, potassium dichromate, sodium chromate wood preservation chromium trioxide leather tanning ammonium dichromate

HOW TO CONTROL THE CHROMIUM EXPOSURE.

If not using TiP TiG, the four best ways to prevent inhaling or ingesting chromium-containing particles are

[1] substituting chromium-free materials.

[2] using exhaust with good ventilation,

[3] careful selection of weld process - consumables,

[4] use low parameters .

A mechanically powered local exhaust hood should be placed at the point where chromium is released into the air. Properly designed and maintained local exhaust ventilation draws off most of the chromium before it can be inhaled. Using local exhaust is far better than relying on dilution of chromium-contaminated air or by natural ventilation through open windows and doors, or ventilation with fresh air brought in through a duct. With the dilution approach, overexposure can still occur at the point of chromium release into the air, or if the dilution air does not mix well with the room air.

AIR PURIFYING RESPIRATORS ARE COMMON BUT HOW EFFECTIVE? Wearing an air-purifying respirator such as a paper mask or rubber mask with screw-in filters is the least effective way to control exposure. In fact, the Cal/OSHA respirator standard (General Industry Safety Order [GISO] 5144 in Title 8 of the California Code of Regulations) allows respirator use to prevent overexposure only as the last resort. This restriction exists because the use of respirators is complex and prone to error, often resulting in inadequate protection.

First, the respirator must be approved for the type of particles in the air; for example, a paper dust mask designed for removing powder particles will not remove the fume particles created by welding. Next, the respirator must be fit-tested to ensure that it fits the wearer's face, and the respirator must be kept in good condition. The fit should be regularly checked. Workers should also be medically examined for their ability to wear a respirator. Even when these and other requirements are met, leakage of contaminated air into the respirator may still occur.

SPECIAL CONTROL MEASURES FOR SPRAYING, WELDING, CLADDING AND PLATING.

Cal/OSHA enforces standards to control workplace exposures to hazardous substances. Cal/OSHA has developed special standards for some workplace processes, including spraying, welding, and plating. These standards are designed to control worker exposure to toxic substances, including chromium. If the provisions of these standards are followed, workers' exposure to chromium will be greatly reduced.

With many global weld shops, sometimes first world shops

can look like the third world shops.

Welding: Cal/OSHA standards GISO 5150 and GISO 1536 require the use of local exhaust ventilation where possible for all "indoor" welding and cutting operations. Further, if stainless steel welding or cutting is done in an "enclosed space" where using local exhaust ventilation is impractical, approved airline respirators must be worn. For "outdoor" stainless steel welding or cutting, approved respirators must be worn; again, an airline respirator rather than an air-purifying fume respirator provides the best protection. Cal/OSHA construction standard GISO 1537 also regulates the welding and cutting of metals coated with toxic substances, including chromium. The chromium coating must be stripped for at least four inches from the area of heat application before welding or cutting. If the coating is not stripped, approved airline respirators must be worn.

[] Spraying: Cal/OSHA standard GISO 5153 requires that spray coating operations be confined to properly designed and ventilated spray booths or spray rooms whenever possible, and sets minimum inward air velocities at the spray booth faces. If you must work in a large spray booth downstream from the part being sprayed, an approved respirator must also be worn.

For large-scale spraying of chromium-containing coatings that involves a lot of back-spray, or that is done outside of a spray booth as in construction work, wearing an approved positive-pressure airline respirator with a full facepiece provides the best protection. This respirator delivers fresh air through a high-pressure hose to a tightly-fitting rubber facepiece that seals from the hairline to under the chin. Some airline respirators replace the facepiece with a loose-fitting hood that covers the entire head; however, these hooded respirators tend to allow some inward leakage of contaminated air.

[] Plating:Cal/OSHA standard GISO 5154 sets minimum air control velocities for local exhaust ventilation systems for chrome plating tanks. Although any chrome plating tank should be equipped with local exhaust ventilation, chromium exposure can be further reduced by placing full or partial covers over the tank. Although covers must be removed to load and unload the parts being plated, covers improve the function of the local exhaust hood. For example, covers prevent strong drafts from windows or fans from carrying chromic acid mist off the tank surface away from the local exhaust hood. Using covers is an effective way to reduce chromium exposure in chrome plating.

The current < May 2006 Permissible Exposure Limit does not adequately protect against lung cancer. We recommend that the amount of hexavalent chromium in the air a worker breathes be kept as low as possible.

If a worker thinks that he may be overexposed, he should talk to his supervisor and or union representative, or other people listed in the "Resources" section at the end of this Hazard Alert. If any worker might be exposed to a substance at more than the legal exposure limit, the employer must measure the amount of the chemical in the air in the work area (Cal/OSHA standard GISO 5155). Workers have the right to see the results of monitoring relevant to their exposure (Cal/OSHA standard GISO 3204). Workers also have the right to see and copy their own medical records and records of their exposure to toxic substances. These records are important in determining whether a worker's health has been affected by the job. Employers who have such records must keep them and make them available to employees for at least 30 years after the end of employment.

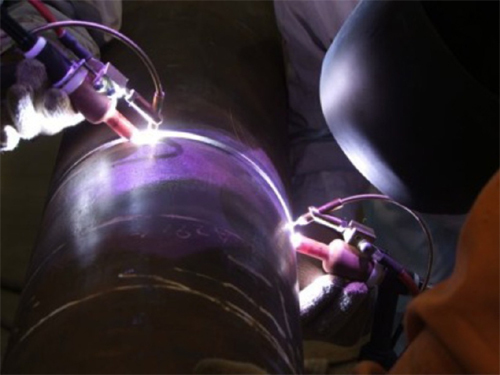

Management - engineers choose the process for those alloys and as you can see on the right we have two welders using TiP TiG (see if you can find the fumes), while the management on the left who did not give a dam, selected the flux cored process for their welders.

YOUR RIGHT TO KNOW: The Hazard Communication Standard (GISO 5194) requires employers to provide workers with information about the hazardous substances to which they may be exposed and to train them to use these substances safely. Employers are also required to have a Material Safety Data Sheet (MSDS) for any workplace product that contains a hazardous substance, and must make the MSDS available to workers or to a treating physician on request. An MSDS is a standard form that lists the chemical contents of a product, describes its health and safety hazards, and gives methods for using and storing it safely. This Hazard Alert is an aid for worker training programs. It does not take the place of a Material Safety Data Sheet or the required employer training.

Failure to comply with GISO 5194 may also constitute failure to comply with the Safe Drinking Water and Toxic Enforcement Act of 1986, popularly known as Proposition 65. Proposition 65 prohibits employers from exposing workers to certain chemicals (including hexavalent chromium) above specified levels without first warning them. These chemicals are on a list of substances "Known to the State of California to Cause Cancer or Reproductive Toxicity." Proposition 65 allows workers to sue an employer for large civil penalties for not providing appropriate warning about listed chemicals.

Hexavalent chromium compounds CR(VI) are most commonly used as a structural and anti-corrosive element in stainless steel, iron, and steel production, and in welding and painting, CR(VI) have been associated with lung cancer and skin disorders

April 2006: OSHA permissable exposure limits for hexavelent chrome. (CR(VI). Final rules effective May 30 2006, go into full effect May 30 2007. Engineering solutions do not have to be implimented till 2010.

Final rule for exposure over eight hours. 5 micrograms of Cr (VI), per cubic meter of air.It used to be 52 micrograms so this is a considerable reduction which should concern all weld shops.

Apart from the reduction OSHA also requires the following

[] Identify and establish areas in the shop where PEL is expected to exceed.

[] Monitor the exposure of employees, not sure if this is an annual or one time only request

[] Establish work practices and provide engineering equipment solutions to reduce employee exposure.

[]Provide repiratory equuipment when PEL cannot be kept under minimum requirement.

[] Provide protective clothing, as necessary for dermal protection, (this should be interesting).

[] Provide when necessary hand washing stations.

[] Train workers on hazards of CRVI and keep records.

MANGANESE Weld Fumes.

Class Action Weld Consumable Lawsuits Manganese and other Alloys.

and their Possible Health Issues.

How to avoid Parkinson's disease:

Kenneth B. Moll & Associates, Ltd. filed a worldwide class action lawsuit in the United States District Court for the Northern District of Illinois against Illinois Tool Works, Inc., et al., the manufacturers of welding products that produce manganese poisoning that can cause Parkinson's Disease.According to the complaint, recent research, case studies and medical literature confirm that there is a causal connection between exposure to manganese welding fumes and Parkinson's disease.

Parkinson's disease is a terminal illness that usually affects people in their late 60's. Welders have shown symptoms of Parkinson's Disease as early as age 45. People who have been exposed to welding fumes containing manganese should be aware of the following symptoms which may lead to Parkinson's Disease: slowed movement, tremors and shaking, loss of coordination or balance, stiffness in body and limbs, slowed or slurred speech, tightening of facial muscles, handwriting worsening, difficulty walking, difficulty turning, anxiety, irritability, depression, mood changes, short term memory loss, and inability to perform normal tasks. Anyone exposed to manganese fumes and experiencing any of these symptoms should contact a physician. According to the complaint, welding sites should use a combination of ventilation and respiratory protection equipment to prevent welders from being exposed to toxic manganese fumes during welding operations. Kenneth Moll said, "the primary goals of this class action are to (1) obtain a Court Order forcing manufacturers to stop the manufacture and sale of welding products that contain manganese and issue a recall, (2) inform the public that welders (pipe fitters, electrical workers, ironworkers, steelworkers, metal workers, plumbers, railroad maintenance workers, piledrivers, millwrights, glass manufacturers, etc.) and others working near welding or pipefitting activity, are at an increased risk of manganese poisoning leading to Parkinson's disease, (3) provide compensation to all victims for death and personal injuries, (4) provide a medical monitoring fund for individuals who have shown symptoms of Parkinson's disease."Welding Rods and Welding Rod Fumes linked to Parkinson's Disease (Manganism, Manganese Poisoning, and manganese-induced Parkinsonism).

The causal connection between welding fumes that contain manganese and neurological injuries have been documented for hundreds of years, dating back to1837. A published report from 1837 described two ore workers who experienced symptoms of parkinsonism induced manganese poisoning. These workers were described as showing symptoms of "fixed gaze, slow movements, rigidity, and tremors,"

Another medical article published in 1932, explained that manganese electrodes should be avoided due to health risks of welders. Incredibly, in 1937, an insurance company published a welding safety booklet stating that manganese in welding fumes "causes a disease similar to paralysis agitans [Parkinson's disease].

Chronic manganese poisoning in the welding profession was even recognized in 1981, by the World Health Organization. Additionally, recent studies have further shown that some welders exposed to welding rod fumes have now developed symptoms of Parkinsonism or Manganism, similar to Pakinson's Disease.

For instance, an unpublished report of 20,000 workers exposed to welding fumes written by Dr. Paul Nausieda, medical director of the Regional Parkinson Center at St. Joseph's Hospital in Milwaukee, found that 10% of the "welding population" developed signs of, or symptoms similar to, Parkinson's Disease compared to 1% among the general population.

While the welding industry denies any cover-up involving the health risks from welding fumes and denies any causal relationship between exposure to manganese and Parkinsonism, the overwhelming evidence points the contrary.

A jury recently awarded $1 million to Illinois man who said he developed Parkinson's disease from years of breathing fumes from welding rods.

In Larry Elam's case, the jury ruled that welding-rod manufacturers are responsible for failing to warn him about potential health problems. Elam, 65, of Collinsville, Ill., said he used rods made and sold by major companies across the country, including Lincoln Electric Co. in Cleveland. The companies argued that there is no link between welding and Parkinson's.

Attorneys for welders say workers suffered neurological damage from welding rod fumes that contain manganese, which stabilizes and hardens the weld. In documents, the attorneys said the fumes can lead to brain damage.

Welding is the process of joining two or more different metals. Welding electrodes

(also called welding rods) contain manganese. Additionally, certain types of welding wire are contain up to 24% manganese. Unfortunately, the process of welding, cause the emission of these manganese fumes to be released into the air as well as carbon monoxide, carbon dioxide, ozone and fluorine. Few weld personnel are provided with proper protection from the weld fumes . The gases may be odorless and cannot be seen with the naked eye.

For over a hundred and fifty years, manganese has been medically recognized as toxic to the brain and central nervous system. Exposure to heavy concentrations of these fumes for as little as three months may produce a progressive condition, referred to as Manganism. Manganism is also referred to as manganese poisoning, and manganese-induced Parkinsonism. In 1963, a toxicologist by the name of Dr. Irving Sax published a book which noted that manganese "affects the nervous

system and can cause paralysis to a degree which may be disabling" and that "widespread... exposure occurs in electric arc welding since most welding rod coatings contain manganese."Parkinsonism is a disabling neurological disorder associated with the following symptoms:

1. Tremors of the arms and hands;

2. Loss of balance

3. Excessive periods of time with little or no blinking, or facial expressions;

4. Drooling;

5. Slow, unsteady and decreased movement;

6. Stiffness in arms;

7. Akinesia

8. Stiffness in legs;

9. Gait changes, including "shuffling of feet" and rigidity in arms;

10. Loss of balance

11. Fixed gaze - Excessive periods of time with little or no blinking, or facial expressions;

12. Drooling;

13. Impaired reflexes;

14. BradykinesiaIf you or someone you know suffers from any of these side effects of has bee diagnosed with Parkinson's Disease, Manganism, Mangan

Comment from Ed:Of course we all know that too many law companies typically will have minimal concern for welders. Class action law suits will put most of the money into the hands of lawers and often drives some good companies out of buisness. At the end of the day in America, those that are injured or killed in the work place are often simply pawns for legal greed. If you feel that you suffered from weld smoke issues, I would recommend you sue for your self and if you want justice you may need to leave the USA. See below.

More on weld fumes and Parkinson's disease?

Plaintiffs in Weld-Fumes Case

Win a Skirmish in Federal Court

By TIMOTHY AEPPEL

Staff Reporter of THE WALL STREET JOURNAL

July 26, 2005; Page D4A federal court in Cleveland has indicated it will allow plaintiffs' lawyers to argue that welding fumes cause Parkinson's disease, which will allow the argument to be made in thousands of lawsuits brought on behalf of workers across the U.S., bringing closer a wave of potentially crippling litigation for the industry that makes and distributes welding materials.

In a draft order distributed to lawyers in the case, U.S. District Judge Kathleen McDonald O'Malley denied a defense motion to exclude testimony that welding-fume exposure causes the serious neurological disorder.

The move doesn't address the underlying question of whether welding fumes can in fact cause Parkinson's, but rather will help shape an avalanche of litigation now poised to move forward in a host of other courts. About 4,500 separate welding cases have been aggregated in front of the Cleveland judge as part of a multidistrict litigation order. Plaintiffs' attorneys estimate there may be as many as another 5,000 such cases in state courts.

The dispute over health dangers posed by welding has raged for decades. The welding process relies on the use of welding rods, which melt to create a bond between the two pieces of metal being joined. This releases fumes laden with manganese, a metal known to cause neurological problems.

There are as many as 500,000 welders in the U.S., but a far larger number of workers are exposed to welding fumes in the workplace. Welding is a ubiquitous industrial operation, used in everything from building ships and bridges to manufacturing plastics and electronics.

Most of the lawsuits aim primarily at current and former makers of welding materials, including Lincoln Electric Co. of Cleveland, A.O. Smith Corp. in Milwaukee, and Airco, a division of BOC Group PLC of London. Suits also have named distributors of welding gear as well as large users, including General Electric Co., Fairfield, Conn., and Caterpillar Inc., Peoria, Ill.

Workplaces are required to provide ventilation for welding operations and breathing gear for those exposed to heavy fumes. Welding materials also come with printed warnings.

However, the basis of most of the lawsuits is that manufacturers of welding materials knew the dangers posed by their products and didn't do enough to reduce the dangers or warn about it."We hope that this is the beginning of the end of the refusal of the welding industry to recognize this as a serious public-health issue that affects hundreds of thousands of people every day," says Drew Ranier, an attorney with Ranier, Gayle & Elliott, a law firm in Lake Charles, La., and one of the lead plaintiff attorneys.

John Beisner, lead council for the defendants in the Cleveland court, said the industry has gone through 10 trials in which Parkinson's disease was alleged, and it has won nine of them. "We thought we'd file a motion [to exclude testimony that welding-fume exposure causes Parkinson's disease] to foreclose further litigation of this issue," he said.

Mr. Beisner said the science isn't there to establish a connection between welding fumes and Parkinson's disease.

He also said it is important to view the "nature of the claims." As part of the court proceeding in Cleveland, litigants were required to fill out a questionnaire. Not all of them have completed this survey, Mr. Beisner said, but of those who have, 70% said they became involved as a result of a screening process in which lawyers invite welders to come in for medical tests. Only 14% said they incurred any medical expenses before they joined one of the cases. Nearly a third also has made claims in asbestos litigation, he added, so they are "repeat litigants."

Federal Jury awards $20.5 million in welding fume lawsuit:

It was reported in the Nov/ Dec 2007, USA "Welding Magazine", that a jury in the US district court in Cleveland, Ohio awarded Jeffery Tamraz, 51 a judgment of $17.5 million, and his wife an additional $3 million in a lawsuit in which Tamraz sued four companies for allegedly not issuing sufficient warning about the dangers of inhaling welding fumes.

Tamraz claimed the fumes gave him tremors, headaches, and symptoms similar to Parkinson's disease. A nine person jury said Dec 5, that Lincon Electric, Hobart Brothers Co. ESAB Group. TDY industries and BOC showed negligence by not sufficiently warning Tamraz of the toxicity of the manganese in their weld consumables.

Manganese and other Alloys. Possible Health Issues.

Manganese is found in most carbon steels, low alloy and stainless steels. Typically manganese levels are higher in electrodes that provide welds with a slag. In contrast to MIG wires, weld fume manganese content is higher in SMAW, GAS SHIELDED & the SELF SHIELDED FLUX CORED wires.

Be especially wary of Self Shielded Flux cored wire and CO2 gas shielded FCA flux cored wires..

[] Overexposure to manganese may injure the central nervous system and result in manganism.

[] Manganism is indicated by symptoms similar to Parkinson disease, which is a neurological disorder characterized typically by

[] Slow body movements.

[] Slow Reflexes.

[] Headaches.

[] Muscle weakness.

[] Speech impairment.,Chromium in stainless and nickel alloys. Human Carcinogen, severe irritation of upper respiratory tract and skin, severe nasal issues. Kidney damage

Cobalt. Hard facing and high temp applications. Human Carcinogen. Chronic cough, pneumonitis, asthma.

Copper. Bronze, brass monel and stainless. Upper respiratory tract irritation, metal fume fever and eye irritation, anemia and skin hair discoloration.

Iron Oxide.Carbon steels and cast iron. Benign pneumoconiosis.

Molybdenum. High strength and stainless steels.Eye irritation and nose mucous issues,Nickel. Some steels stainless and nickel alloys. Asthma, dermatitis, lung or nasal cancer.

Vanadium. Some steels stainless and nickel alloys. Respiratory / eye irritation. Irritates wet skin, bronchitis, cough and nasal bleeding.

Zinc. Brass / Galvanized coatings. Metal fume fever, tired, sleepy

Note: Very good article on this subject by Mike Harris in Aug 2005 Fabricator magazine.The AWS-commissioned Study on Welding and Exposure to Manganese

In July 2004, the AWS Safety and Health Committee engaged an outside independent expert, Woodhall Stopford MD, MSPH, of the Duke University Division of Occupational and Environmental Medicine, to review the literature of published articles related to the neurotoxicology of manganese, particularly including manganese found in welding fume.

The Committee's intention was to obtain an objective appraisal of the relevant literature by an authoritative expert, and to receive a written report that would reflect the expert's own views independent of those of AWS, the Safety and Health Committee, any Committee member, or any organization or person with a direct interest in welding matters.

The Committee's plan from the outset was that it would promptly make Dr. Stopford's report part of the public record whatever its conclusions, and regardless of whether the Committee, or any Committee member, would or would not ultimately agree with all of the conclusions or with any of Dr. Stopford's specific findings or stated views. Dr. Stopford has now completed his report which finds:- Parkinson's Disease and manganism are separate and distinct illnesses.

- Published research shows that exposures associated with manganism have occurred primarily in nonwelding occupations such as the mining and manganese alloy fabrication industries.

- Studies have not supported that welders have a higher incidence of Parkinson's Disease compared to the general public or that welding is a risk factor for Parkinson's Disease.

- Studies have not supported that welders have a higher incidence of an earlier onset of Parkinson's Disease compared to the general public.

- Studies of Parkinson's Disease patients have not supported a relationship between welding and Parkinson's Disease.

Download the full report https://www.aws.org/duke_study/duke.pdf

Note from Ed. Ref the above i would want to look at the source, the expertise and the scope of those articles which Imn sure i would find much of the data is biased, ignorant or lacking in reality,

Health issues in welding on Galvanized Steels [Indiana]

Jun 9, 2001.

From Ron. For anyone interested, I just came across this page while looking into metal fume fever. I have learned a valuable lesson from working on galvanized. In fact, I am still feeling the effects of "metal fume fever" as I type this! I welded a small repair on a galvanized part. The material was very thin so I used a 1/16th stainless electrode. I neglected to use a proper respirator or ventilation. For the next 48 hours I have had flu-like symtoms. Believe me when I say, it's not fun sitting on the toilet all day! LOL ...I do believe anything application to galvanize that breaks down it's composition and releases zinc oxide into the air is a dangerous health risk. Of course I compounded my problem by inhaling the chromium fumes from the stainless electrode.Needless to say....this will be my first and last experience with "metal fume fever"......I hope! Ron Enns

May 5, 2005. E-Mail.

Dear Ed. My husband welded on galvanized steel 3 days ago. That evening he started feeling very ill, this is the 4th day and he still is not feeling any better. His symptoms include high fever, chills, severe body ache, and chest pain. Does this sound like it could be galvanized poisoning? If so should it be lasting 4 days, and is there anything we can do for it?Thank you for what you do,

April Franklin

UA Local - Lansing, MI.

May 3, 2005.

Ed, I am the wife of a welder. He has been welding on Galvanized steel for the last 4 yrs. He has been pushing for better exhaust for over the last 3 yrs. Now his voice is very bad, sometimes when he gets home from work you can hardly understand him, or hear him from his voice being so bad.. Most morning's he is throwing up before work. He also says how it feels like something is in the front and side of his throat. I have been personally there on the weekends with him when he works and when he is done welding it looks like it is snowing around him from welding galvanized..And I was wondering just how dangerous it really is for him to be welding and breathing galvanized.. And if anyone knows what damage he is doing to himself..We have been married for 22 yrs. and I don't want to loose him to his profession. Any information anyone can give me would be greatly appreciated.

Thank you,

April Baker

Reply From Mr Piatkiewicz Galvanizers Assoc.Metal fume fever originating from zinc is associated with flame cutting or welding operations on galvanized steels. Any operations that have molten zinc approaching its boiling point, 911 Degrees centigrade, may emit significant amounts of zinc 'fume' which in any event oxidises rapidly to form zinc oxide. It is this airborne particulate form of zinc oxide, with a very small diameter (less than 1 micron in size- 1 millionth of a meter in diameter) which is associated with the onset of metal fume fever. This fever is as it sounds, with the symptoms of the 'flu'.

There are no known adverse effects from this fever. However this is not a reason not to avoid these symptoms! Taking the usual precautions of good working practices, minimising exposure with good ventilation, using extraction equipment all help.

Cheers,

Wieslaw Piatkiewicz

Galvanizers Association - Sutton Coldfield, West Midlands, UK.

Reply from Ed. Dear House wife. You have just read a complete BS reply from a highly biased source that sits in an air conditioned office as he works for the Galvanizers Association. Galvanized applications are terrible for welding and in many instances at too many plants no one in the front air conditioned office will give a dam about the galvanized coating thickness and the fume effects to the welder and to those that work in the vicinity.

In one plant that makes galvanized coated greenhouse parts, I MIG welded the galvanized parts for less than 2 hours examining the process variables. I felt sick for the rest of the week. Any weld fumes that have this immediate impact on any human should simply be avoided (let them coat after welding) or only welded when 100% ventilation is provided. if your husband enjoys life, tell him to get a job elsewhere and to document what he does with photos and hopefully you can one day sue the weld shop and I would also sue that Galvanizers Association for there BS...

Note: I have spent 50 plus years in this business and over those years I have been off work or felt sick from weld fumes from many alloy applications such as, galvanized, copper, aluminum, self shielded carbon steel wires, manganese, stainless, nickel, brass. One time when welding gage stainless at a Texas refinery, I was showing maintenance welders how to MIG weld thin gage stainless parts. Unfortunately a small part of the protective plastic wrapper was left on the back side of the stainless, and within 3 minutes of welding, both myself and my assistant passed out from the miniscule fumes generated. This is weld reality. What also is weld reality, is apart from getting cancer that started in my throat ten years ago, (in remission), in 2015, there are thousands of weld shops in GOD BLESS AMERICA, where every day the welders are breathing fumes from alloys and they have no information on the weld fumes real dangers, (information that every weld consumable mfg. has), and the weld shop management is not providing the most effective means to protect the workers from both the fumes and alloy weld dust particles that result from grinding.

This is the only process in which you should not have a concern for weld defects, weld distortion or stainless, duplex, nickel or alloy fumes.

Stainless - Inconels - Duplex - Hastelloy - Brass - Cu - Monel - Titanium - All alloy welds.

When using TiP TiG management has made ta decision to utilize a process that;

[] has no flux and produces no slag,

[] only uses an inert gas,

[] readily welds 3 to 6 times faster than TIG,

[] uses Electrode Negative which in contrast to MIG and flux cored, distributes more of the arc heat into the part,

With benefits like this, it's no wonder that TiP TiG is only process in which weld fumes, spatter, distortion and defects should not be a concern..