|

At www.tiptigusa.com, you will find a weld process that always produces superior weld quality than TIG, and is 100 to 500% faster. |

Welcome to the world's largest web site on MIG , Flux Cored and TIG. Weld Process Controls & Best Weld Practices. To get to the root cause of MIG & Flux Cored weld issues, requires Weld Process Control - Best Practice Expertise, & lots of Weld Reality. The site provides the MIG - Flux Cored and TIG weld information and data required to attain the highest possible manual and robot weld quality, always at the lowest possible weld costs.

This web site was first established in 1997 by Ed Craig. Contact Ed. ecraig@weldreality.com

Duplex information and weld process resolutions to the problems you can expect when welding duplex parts.

CAREFUL PROCESS SELECTION IS THE KEY

TO AVOIDING ALLOY WELD PROBLEMS.

300 to 500% faster than TIG - Lowest Possible weld heat - Highest possible weld quality - No weld fume concerns - No spatter or weld cleaning, its called TiP TIG.

For those alloys that are weld heat sensitive, there is no better manual or automated weld process than the process that Ed Craig and his buisness partner Tom O'Malley introduced to North America and Australia, that process is called TIP TIG.

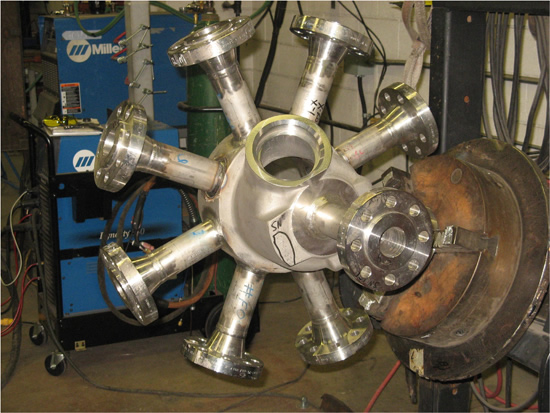

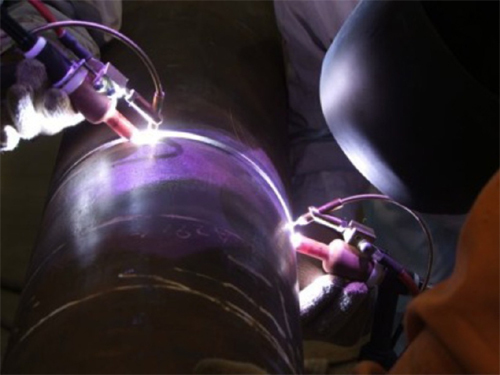

TIP TIG (shown above and below) welding at 260 AMPS on a 12 mm stainless tanks. This is the only process in which you should not have a concern for alloy weld defects metallurgical issues or weld distortion, or for alloy weld fume concerns.

.

TIP TIG A SIMPLE PROCESS TO AUTOMATE.

Note the lack of weld fumes and spatter with TIP TIG.

Stainless - Inconels - Duplex - Hastelloy - Brass - Cu - Monel - Titanium - All alloy welds.

When using TiP TiG management has made a decision to utilize a process that;

[] has no flux and produces no slag and no spatter,

[] only uses an inert gas so cleanest possble welds,

[] readily welds 3 to 6 times faster than TIG,

[] uses Electrode Negative which in contrast to MIG and flux cored, distributes more of the arc heat into the part producing lowest possble weld heat with smallest HAZ.,

[] Easier to use than regular TIG as it requires only one hand and no foot control.

[] Weld pool agitation and high current ensures least potential for weld fusion - porosity.

With weld benefits like this, it's no wonder that TiP TiG is the process of choice for most steel alloy weld applications.

.

Stainless steel evaporators and duplex components.

WHEN DEALING WITH COSTLY ALLOY WELD APPLICATIONS, WISE WELD PROCESS - EQUIPMENT AND CONSUMABLE SELECTIONS ARE SUPPOSED TO COMMENCE IN THE FRONT OFFICE:

Once you have read all the typical weld - heat related problems that will be generated withe those Duplex alloys using either the pulsed MIG - regular MIG - TIG - Flux Cored or the SMAW process, the good news is none of the common duplex weld issues should be generated if the management selects the weld process thats most suited to not only duplex, but to all heat sensitive alloys. That process is called. TIP TIG.

Info from Avesta: Pulp Paper Industry and the use of stainless steels and duplex:In modern pulp and paper mills, nearly all key equipment (digesters, bleaching systems, evaporators, storage tanks and paper machines) are made from various types of stainless steels. Approximately 5,000 to 6,000 tonnes of stainless steel go into a large new pulp and paper mill. On top of that, there is piping, welding consumables and auxiliary equipment. The typical materials used are standard austenitic, duplex and high-alloy super-austenitic stainless steels.

Currently, the high price of the alloying elements in the raw materials is one of the reasons why manufacturers serving the pulp and paper industry are showing increased interest in duplex steels. However, the most important factor is that, even though the nickel and molybdenum content is generally low, duplex steels have very good properties. “Previously, so-called ‘acid-resistant’ steels were used when the sulphite process (an acid process) was used in cooking paper pulp. Now that the industry is increasingly switching to sulphate or other alkaline solutions, such steels are no longer optimal,” says Lena Wegrelius.

Stress corrosion presents the greatest risk in alkaline cooking. Stainless steels with a high chromium content, low molybdenum content and duplex microstructure are optimal for these environments. Furthermore, the strength of duplex steels is "twice" that of standard steels. Consequently this allows pressure vessels to be built with thinner walls. Duplex steels are more cost-efficient austenitic steels.

Avesta has a new duplex grade, LDX 2101®, which is excellent for the paper industry. However, its a fact that the choice of materials when building new plants or machinery is not determined solely by what is best for the application. For example, in Latin America, mills are favoring their own local producers and these producers do not always manufacture duplex steel. In those cases, standard materials are being used. In Chinese steel manufacturers are also producing duplex steels.

How did the Corrosion Test do?

.

The Duplex Family:

To cut through the unique trade names for some duplex alloys you may wish to reference the UNS number when ordering to the standard specifications in order to get the desired grade. Many of the duplex grades have become known by a number that reflects their typical chromium and nickel contents. For example the 2205 grade will have 22% Cr and 5% Ni. These composition-based names, used by many producers, have recently been added to A 240 and are being added to the ASTM specifications for other product forms.

Please note, all the fume safety precautions as noted in the stainless fume section of this site should be adhered to when welding duplex.

[a] Lean duplex: Grade 2304. UNS (S32304) contains little or no deliberate Mo addition. Corrosion resistance equiverlent of 316L

[b] Common duplex: Grade 2205. UNS (S32205) accounts for vast majority of duplex use;

[c] 25 Cr duplex: Grade 255. UNS (S32550) and S31260;

[d] Superduplex: Grade 2507. UNS (S32750). Has 25-26% Cr and increased Mo and N.

[e] Hyper Duplex: Grade 2609..

Both the peroxide reactor and the oxygen reactor, behind it, are manufactured from 2205 duplex stainless steel.

.

Info From Avesta: The commercial development of stainless steel occurred side by side with that of the modern pulp and paper industry. This was a phenomenon of 1940’s northern Europe. The unique collaborations between engineering companies (developers of new and more efficient pulp and paper processes) and steel mills have led to unsurpassed expertise in stainless steels for various pulp and paper applications. They have also led to the development of new steel grades such as 254 SMO® and LDX 2101®.

To test how it's steel grades stand up to various environments, Outokumpu has a number of research and development collaborations with mills, machine builders, research institutes and engineering companies. Amongst other projects, Lena Wegrelius mentions that with an inspection company, Inspecta. In this, field tests are being run in digester and evaporator environments at the Smurfit Kappa Kraftliner pulp and paper mill in Piteå. “We are also working with Chempolis Oy in Finland. The latter company is looking at processes for cooking pulp from raw materials other than wood. This is of future interest for the Asian market,” she declares. In China, for example, trials are being conducted with the common reed and residual products from arable and rice farming. New processes and steel grades may be necessary here. What else can be said about developments in pulp and paper? “For environmental reasons, the industry is using more and more recycled paper in its raw materials. It is often said that fibres can be used seven times before they are finished. Recycling processes are thus becoming increasingly more important in pulp production,” concludes Lena Wegrelius..

.

There was only one process that could ensure the high weld productivity with no weld distortion or rework, and for this Alberta company, Tip TiP was the process of choice.

.

AVESTA NEW DUPLEX FLUX CORED WIRE:

Avesta FCW-2D LDX 2101There is now a new and improved version of Avesta Welding’s flux cored wire for welding Outokumpu’s new duplex steel, the LDX 2101®.Avesta FCW-2D LDX 2101 gives a duplex weld metal that combines excellent mechanical properties with good corrosion resistance. In both the flat and the horizontal-vertical (PC) positions, weldability is very good Positive direct current (DC+) is used for welding flux cored wires. Compared with MIG welding, the flux cored wire parameter range is considerably wider. Avesta FCW-2D is an 0.045 1.2 mm wire supplied in a layer wound on 15-kilo wire basket spools. Avesta Welding’s range of filler metals for welding LDX 2101® also includes covered electrodes and solid MIG, TIG and SAW wires.

Note from Ed there is no flux cored wire and no MIG weld transfer mode that can produce the weld quality and the metallurgical properties that can be attained from the TIP TIG process.

.

AVESTA 2304

For welding storage tanks, recovery boiler pipes, oxygen reactors, etc. in duplex stainless steel 2304 (EN 1.4362, Outokumpu 2304). Avesta Welding is the first supplier in the

world able to offer a complete range of matching filler metals for this duplex grade. The range comprises covered electrodes, flux cored wires and solid wires (TiP TiG/MIG/TIG/SAW).

AVESTA 2205

For welding batch and continuous digesters, oxygen delignification and pressurized peroxide reactors, press washers, pulp towers and filters, etc. made of 2205 duplex stainless

steel (EN 1.4462, Outokumpu 2205). Giving excellent mechanical properties and corrosion resistance, Avesta 2205 has a long record of success in these applications.

AVESTA 2507/P100

For welding super duplex 2507 (EN 1.4410, Outokumpu SAF 2507) and similar grades. Avesta’s 2507/P100 range of highly alloyed super duplex consumables provides better

strength and corrosion resistance than ordinary duplex fillers.

AVESTA LDX 2101

Specially designed for welding Outokumpu LDX 2101 (EN 1.4162), the new high-strength low-alloy duplex stainless steel. Thanks to its superior strength and good corrosion resistance in alkaline environments, this cost-efficient material is a maintenance-free option for railings, walkways, storage tanks and even hydrogen peroxide reactors in pulp bleaching.

With Avesta LDX 2101, it is easy to achieve a sound weld that, as regards corrosion resistance and mechanical properties, “matches” the parent metal.

Duplex 130 ton Urea Reactor

.

Article From Avesta. Jaraguá of Brazil manufactured and delivered a complete urea reactor to Petrobras/FAFEN in Camaçari (Brazil), all the stainless steel plates and welding consumables came from, respectively, Outokumpu and Avesta Welding in Sweden. The reactor, which was the first to be produced in South America, weighs 130 tonnes. Besides conventional non-destructive testing, the reactor was subjected to helium leakage tests and positive material identification (PMI). Furthermore, all stainless steel (welded joints included therein) were corrosion tested as per ASTM A262’s “practice C” (Huey test). The special technique developed to measure the gap between shell and lining (maximum permitted limit of 3.0 mm) is worthy of individual highlighting. Compared with other assignments, one of the greatest differences for Jaraguá was that, to guarantee perfect handling and cleaning of the stainless steel, manufacture of the reactor was kept entirely separate from other production.

Note from Ed. While Avesta and Sanvik are an excellent source for duplex product and info, however it's unfortunate that more than a decade has passed and there "this is the way we have always done it" engineers and mangers still have not figured out the benefits from the manual / automated TiP TiG process for both their alloys and for their customers such as Jaragua above. TiP Tig would have simplified this appalication and dramatically lowered the weld costs..

High productivity welding of the new lean duplex stainless steel,

LDX 2101® (S32101)

With their strengthening in the mid 1980's, duplex steels increasingly provided an alternative to conventional austenitic steels. They were then predominantly used for chemical tankers as well as process vessels and storage tanks in the pulp and paper industry. It is the good combination of strength and corrosion resistance that makes duplex stainless steels so attractive. However, in the beginning, the duplex grades were primarily seen as alternatives to high-performance austenitic grades (e.g. 904L and 254 SMO®) rather than as alternatives to conventional grades (e.g. 304 and 316). This limited their use in general construction. Here, high strength is needed rather than high corrosion resistance. Developed by Outokumpu Stainless, LDX 2101®, the new "lean" duplex stainless steel, is now used in a very wide range of applications.

General purpose and structural applications are just two examples. The high strength and good corrosion resistance of LDX 2101® also make it extremely suitable for a variety of storage tanks. This article focuses on examining how high productivity welding methods using Avesta LDX 2101, can be optimised to maximise the good corrosion resistance and mechanical properties of duplex LDX 2101 stainless steel. Strength and corrosion resistance Of the duplex grades currently on the market, LDX 2101® has the "least alloyed" chemical composition with a nickel content of just 1.5% (balanced with 5% manganese and some 0.22% nitrogen), LDX 2101 offers high mechanical strength and corrosion resistance at an advantageous price. Nickel is an expensive metal. Furthermore, its price fluctuates widely over time. This can present major difficulties when estimating the total cost of a construction.The chemical composition of LDX 2101 is balanced to give a microstructure with approximately equal amounts of ferrite and austenite. Thanks to the high nitrogen content, austenite re-formation after welding is rapid. In general, corrosion properties are as good as, or better than, those of the Cr-Ni grade EN 1.4301/ AISI 304. Furthermore, the steel's duplex structure and high nitrogen content result in a mechanical strength almost twice that of ordinary, austenitic steels.

The high strength of LDX 2101 steel can be used to optimise the design of various storage tanks. On top of this, the steel's cost efficiency can be fully exploited by selecting the correct filler (Avesta LDX 2101) and welding method.Better properties with matching filler metals Because it is optimised to ensure the best welding characteristics and mechanical properties, the matching Avesta LDX 2101 filler should be used to weld LDX 2101® duplex stainless steel. To obtain a suitable ferrite/austenite balance in the weld metal, Avesta LDX 2101 is over-alloyed with nickel.

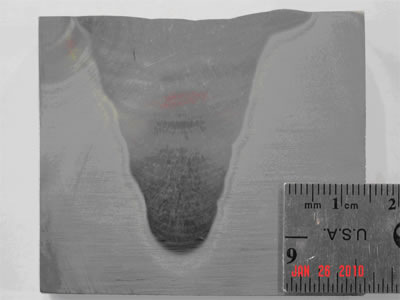

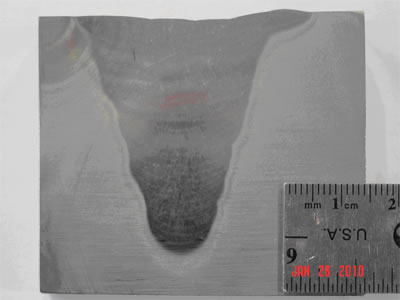

The microstructure of metal arc welded LDX 2101 has a typical duplex appearance with 30 - 65% ferrite.Testing of LDX 2101 welds has shown that tensile strength is higher than 680 MPa / 99 ksi and that fracture most commonly occurs in the parent metal. Bending tests to 180° with a 3 x t mandrel have shown no signs of cracking. Excellent results are obtained when welding LDX 2101 using all conventional methods - TiP TiG - SMAW, FCAW, MIG, TIG and SAW, however the TIP TIG process should always deliver the best possible weld - metallurgical results.

Ed and Tom introduced TIP TIG to N. America and Australia.

Duplex welds and the TiP TiG process. It's not sales talk, it's weld reality. The unique semi-automatic and automated TIP TIG weld process provides the widest weld joules range, the lowest possible weld joules and always the highest possible weld quality. Its a process that requires the least skills for pipe welds, and as you can see above always produce the lowest possible weld fumes..

Aug 2008. A new lean duplex stainless steel grade EN 1.4062 (UNS S32202) has been developed by Industeel and Ugitech by combining low nickel content with a nitrogen addition but without an increase in manganese. Nickel is reduced by a nitrogen addition to develop a microstructure containing approximately 50% ferrite and 50% austenite. After a preliminary study with laboratory heats, several industrial heats were produced with composition 22Cr, 2Ni, and 0.2%N.

Another good source of Duplex Weld Data / Electrodes is Sanvik / ESAB.

July 2008. Sandvik Materials Technology has launched a hyper duplex stainless steel tube material which is designed to improve umbilical performance in increasingly demanding subsea environments. Sandvik SAF 3207 HD is designed specifically for deepwater, high temperature, and extreme pressure applications.

Sandvik SAF 3207 HD provides a tensile strength of 980 to 1180MPa and a maximum operating temperature of up to 90C. This compares with a tensile strength of 800-1100MPa and maximum water temperature rating of 65C for the company’s standard super-duplex grade SAF 2507. SAF 2507 can be deployed in water depths greater than 2000m. However, as the pressure at the seabed increases with depth, the wall thickness of the tube eventually becomes so great that it can become uneconomical to purchase all the material required.

2010: THE DIFFERENCE BETWEEN STAINLESS AND DUPLEX:

Duplex steels offer great mechanical properties and excellant corrosion resistance. The primary difference between austenitic stainless and duplex steels is the duplex offers a balanced microstructure of approx. equivalent volumes of ferrite and austenite. Typically the duplex steel will have a weld ferrite content of 40 to 60% and the weld 25 to 40 % ferrite. A 25% to 50% ferrite range is desirable.

In comparison to traditional austenitic stainless, the duplex, two-phase microstructure and high chrome / Mo can result in duplex applications that have;

[a] higher resistance to stresses,

[b] higher resistance to pitting corrosion cracking,

[c] improved intergranular corrosion resistance.

Note: Be aware of achieving too much or too little ferrite. Rapid quenching of the duplex weld as found in arc strikes or small welds on large parts should be avoided as this can result in very high ferrite content > 60%. The extra high ferrite welds can result in low toughness or low corrosion resistance.

Ferrite in duplex results in lower coefficient of thermal expansion in contrast to austenitic stainless resulting in less weld distortion potential.

One reason TIP TIG is the process of choice is when dealing with alloys and applications that are heat sensitive, and especilly when welding duplex which is sensitive to excess ferrite formation during "rapid weld quenching" , the TIP TIG process provides the "widest possible weld joules range" so no matter what the application alloy is, or no matter what the "part thickness" or weld position is, with TIP TIG there are optimum weld parameters that can be used to deliver the desired weld joules.

Corrosion Potential Information from Sanvik..

.

This data is from Sanvik: Materials used in oil and gas extraction are affected to several different types of corrosion, often caused by seawater and spray. The types of corrosion, which can occur on stainless steels in marine environment, are pitting and crevice corrosion, and for standard austenitic grades also stress corrosion cracking (SCC), if the material temperature is above 60°C (140°F). These are all localised attacks – general corrosion need not be considered for stainless steels in seawater. High temperatures, high chloride contents and low pH values increase the risk of localised attacks in any chloride-containing environment. Of these, temperature is usually the most influential factor.

However, there is a fourth important consideration: the electro-chemical corrosion potential of the environment. In seawater, this potential is affected by biological activities on the steel surface. Since seawater is, in a sense, a living corrosive environment, it is sometimes difficult to define exactly what the service conditions will be. At normal seawater temperatures, a biofilm will form on the steel surface and result in a corrosion potential of +300 to +500 mV/SCE.At temperatures above ~40°C (100°F) the biological activity will cease and the corrosion potential will drop. The use of continuous chlorination, to stop marine growth, may increase the corrosion potential to values as high as +600 to +800 mV/SCE. This, however, can be avoided through the use of intermittent rather than continuous chlorination.

Benefits over Cu and CuNi-based alloys:

Stainless steels are very resistant to erosion corrosion compared with Cu and CuNi-based alloys, which are very sensitive to this form of attack. Water in harbours, around offshore platforms, and near chemical plant sites is often contaminated e.g. with ammonia (NH 3 ) and sulphides (S 2- ). These compounds, even in very small quantities, cause localised attacks on copper-base alloys, while stainless steels are not affected at the impurity levels involved.

Sour corrosion: Wet and sour service: The corrosivity of an oil and gas well is increased by the presence of chlorides in water solutions, carbon dioxide, and hydrogen sulphide.The environment is considered sweet as long as no hydrogen sulphide is present. Carbon dioxide alone can however cause high corrosion rates on carbon steel, since it is acidifying the solution. This is further accelerated if chlorides are present.

Sour environments are defined when the partial pressure of hydrogen sulphide is above 0.05 psi. At higher partial pressures, the corrosion rate on carbon steel is substantially increased by means of making the water phase more acidic and by forming iron sulphide scale. Sulphide Stress Cracking (SSC) is common in high strength steels containing martensite. It can also occur in ferritic steels.

Stainless steels are different. Sandvik Sanicro 28, Sanicro 29, SAF 2205 and SAF 2507 grades are completely resistant to corrosion in wells rich in carbon dioxide with a high amount of chlorides in the water phase. If hydrogen sulphide is present, there is still no general corrosion, but the risk of localised corrosion increases, especially with regard to SSC.

The NACE TM-0177 test.

Experiments have been carried out at room temperature in accordance with the NACE TM-0177 test (5% sodium chloride, 0.5% acetic acid, saturated with hydrogen sulphide).The threshold stress for cold-worked Sandvik SAF 2205/22Cr is about 90% of the yield strength, which is very good when compared to results for high strength, ferritic stainless steels.

Sandvik Sanicro 28, in the cold-worked condition, results in no failures up to very high stress levels. The high alloy duplex stainless steel Sandvik SAF 2507 is also resistant to cracking in the solution-annealed condition.

In general terms, this test shows that Sandvik Sanicro 28 has a higher resistance to sulphide stress cracking compared to SAF 2205/22Cr, which is much more resistant than 13Cr. Sandvik Sanicro 29 has an ever higher resistance to localised corrosion and sulphide stress cracking than Sandvik Sanicro 28.

It should be remembered that the chemistry of the “NACE solution” is not representative of the conditions in most sour oil and gas wells. This is especially true for acidity, where the pH value is lower in the NACE test. Results from the NACE TM-0177 test, therefore, should not be used for determining the suitability of different grades, but more as a ranking test. Other tests, more representative of actual service conditions, must be used to determine the suitability of different grades. Practical experience of specific grades is, of course, extremely useful.

Visit Sanvik's web site for more excellent data on stainless and duplex products, however if you want the best stainless MIG process control data visit here,,

The Metallurgy of Duplex Stainless Steels.Most duplex have an alloy range of,

Cr - 22 to 26% (fume hazards).

Ni - 4 to 7%.

Mo - 0 to 3%.

With 0.1 to 0.3 Nitrogen, (no nitrogen will be in filler metals)

Nitrogen plays an important role of present day duplex alloys. Nitrogen is a potent austenite stabilizer. The addition of nitrogen to the duplex steel will promote structural hardening by a solid solution mechanism. The nitrogen therefore will raise both the yield strength and ultimate strengths of the duplex without impairing toughness.

Nitrogen cannot be added to the filler metal as it can not transfer across the arc. When welding nitrogen can be added to the weld through the shielding or purge gas.

.

MIG GAS MIXES: See Ed's unique MIG gas mixes that he developed in the 1990s for welding Duplex. Check the MIG gas section.

Too much nitrogen in the gas can result in a layer of austenite on the weld surface, this can result in weld strength reduction and less resistance to stress corrosion cracking.

A loss of nitrogen from the steel or weld can lead to an increase in ferrite content and a reduction in corrosion resistance.

Duplex steels are a mix of both bcc ferrite and fcc austenite crystal structures. The percentage of each phase will be dependent on the alloy composition and heat applied. The majority of duplex steels contain approx. equal amounts of ferrite and austenite phases when in the annealed condition.

Note: Don't use nitrogen or any reactive gas with TIG as it will simply contaminate the TIG tungsten..

.

.

Differences between Duplex and Austenitic Stainless Steels.In contrast to austenitic 300 series stainless, duplex steels contain a much smaller nickel content and their price is supposed to reflect the lower nickel content. With high chromium content, the duplex alloys provide;

[a] excellent pitting and crevice corrosion resistance,

[b] resistance to chloride stress corrosion,

[d] the two phase duplex mixture also reduce the risk of intergranular attack,[c] duplex stainless steels are typically twice as strong as common austenitic stainless steels,

[d] The thermal expansion of the duplex grades is intermediate to that of carbon steel,

[e] The thermal conductivity of the duplex stainless steels is also intermediate to that of carbon steels.

[f] With austenitic steels hot cracking can be a problem aggravated by fully or predominantly austenitic solidification, and by the combination of high thermal expansion and low thermal conductivity. (Hot cracking should not be a concern with the TiP TiG process), or by adjusting the composition of the stainless filler metal to provide a significant ferrite content.

[g] In contrast, duplex stainless steels have good hot cracking resistance. In contrast to austenitic stainless, from a weld perspective the duplex alloys are not prone to solidification HOT cracking during welding.

[h] Because of their high chrome content, duplex stainless steels are prone to the 475°C embrittlement, so duplex applications are typically restricted to application temperatures below 300°C.

[i] Duplex steels thanks to excellent mechanical properties (almost twice the strength of austenitic) will permit the use of "thinner wall thickness" while provide the corrosion resistance of Austenitic steels.

[j] The duplex alloys will ALSO provide poorer toughness than austenitic stainless steels.

[k] Duplex provides good resistance to pitting corrosion and chloride induced stress corrosion cracking in combination with high strength and other good mechanical properties.

The Duplex Family:

To cut through the unique trade names for some duplex alloys you may wish to reference the UNS number when ordering to the standard specifications in order to get the desired grade. Many of the duplex grades have become known by a number that reflects their typical chromium and nickel contents. For example the 2205 grade will have 22% Cr and 5% Ni. These composition-based names, used by many producers, have recently been added to A 240 and are being added to the ASTM specifications for other product forms.

[a] Lean duplex: Grade 2304. UNS (S32304) contains little or no deliberate Mo addition. Corrosion resistance equivalent of 316L

[b] Common duplex: Grade 2205. UNS (S32205) accounts for vast majority of duplex use;

[c] 25 Cr duplex: Grade 255. UNS (S32550) and S31260;

[d] Superduplex: Grade 2507. UNS (S32750). Has 25-26% Cr and increased

Mo and N.

[e] Hyper duplex: Grade 2609.

Chemical tankers use large amounts

of duplex and stainless steels

The most common stainless gradel used in chemical tankers is the duplex grade 2205, and 316LN steel is also common. The duplex steels in contrast to the austenitic grades have a great advantage in that they provided high strength with excellent corrosion resistance, which allows the plate thickness to be reduced by as much as 30%.

Weld Data for Duplex.

The high chrome duplex steels are sluggish when welding (look for weld fusion issues from pulsed MIG and MIG short circuit). Duplex welds are similar to most stainless steels, however, to attain the Duples Metallurgical Benefits, (something the welder does not see), it's very important with duplex to ensure the weld personnel follow the pre-qualified weld procedure data and practices down to the smallest details.

FERRITE CONTENT: Duplex, keep your eye on the "Ferrite Content": To attain a good austenite reformation in the weld's heat affected zone, (HAZ), present day duplex steels will have an optimum ferrite-austenite ratio of approx. 50%, while the welds will typically contain approx. 30 to 40% ferrite.

TOO MUCH FERRITE IN HAZ: If more than 70% ferrite is introduced into the weld's heat affected zones the HAZ would be close to fully ferritic and in contrast to the duplex weld the HAZ of the weld will produce inferior mechanical / corrosion properties. A ferrite count using a ferro scope is a popular method to measure the ferrite on the welds and HAZ. An acceptable phase ferrite balance in the HAZ is typically 30 to 70%..

Ed at rear training ship yard welders. Duplex Jobs. Educate the welders on the heat related issues generated with duplex. Then provide them with the best possible weld process - consusmables, process control - best practice training and forgiving weld procedures.

Always remember to remind those that provide the duplex welds, the prime concerns will be from what the welders don't see. Tthe typical duplex stainless steels weld problems will be associated with either lack of fusion or from problems in the weld's heat-affected zones. The HAZ problems are typically from a loss of corrosion resistance and toughness, or post-weld cracking.

THINK ABOUT THE DUPLEX WELD COOLING RATES: Slow weld cooling can reduce ferrite and promote an increase in austenite. In contrast Rapid cooling of the molten weld or the weld's HAZ,

(could be from low parameters - small welds on thick parts) can promote an increase in ferrite. remember rapid weld cooling occurs when welding at fast rates and fast rates typically occur with small weld beads < 3/16 or faster weld speeds that (> 18 inch/min). Rapid cooling also can occur when when welding on good heat sink, or thick parts, and on clad welds and root passes, (thin fast solidfying welds). Also if required a small pre-heat 100 - 150F can slow down cooling. To compensate for rapid cooling and the potential for an increase in the ferrite, the weld electrodes and wire will typically contain an additional 2 to 4% nickel which will help promote the austenite formation.

Note: Duplex applications "should not be welded without filler metal" as as excess ferrite will result. If no or minimal filler metal is utilized consider a solution anneal.

ELIMINATE WELD REWORK AND SCRAP: After the weld procedure is complete, before welding any costly duplex job, provide test welds on scrap parts that replicate both the weld joint and the part thickness. Then test the WELD - HAZ ferrite and use the information above to either increase or decrease the ferrite. As TIP TIG offers the widest possible weld joules range, its almost impossible to screw up ferrite content requirements when using the TIP TIG process.

DUPLEX AND COLD CRACKS: If the ferrite is too high in the HAZ, tougness could be a concern. Cold Delayed Cracks could happen in the duplex HAZ, especially on highly stressed rigid parts. The strange solution is to Reduce the Weld Heat through parameter adjustments, faster weld speeds and change weld sequence.

In the duplex weld heat affected zones, you can have a reduction in both the corrosion and toughness. The toughness reduction can sometimes lead to post weld cracks in the HAZ. To minimize the duplex post weld HAZ cracks, the weld procedure should reduce the time at temperature in the red hot range. To achieve this use moderate sized stringer passes rather than larger weld passes, or weaves, (reducing weld size allows faster weld rates = lower weld heat input, while larger / wider welds = slower weld speeds = higher heat input). Keep single pass stringer weld sizes similar to the 1/4 (6 mm) size fillets and use a max interpass temp of 100C..

PRE-HEAT? Pre - heat, duplex steels versus pre- heat for traditional stainless. Duplex steels in contrast to austenitic stainless can be sensitive to hydrogen while welding, this is due to the higher ferrite content in duplex alloys which typically are equal amounts of ferrite and austenite.

HYDROGEN CRACKING? Note: Hydrogen Induced Cracking, (HIC) with duplex alloys can occur when the weld ferrite exceeds > 55 FN. In contrast with stainless austentic steels, with these nickel based alloys, you end up with have a face centered cubic structure and a low FN ( <12 FN) which is not bothered by HIC.

So with duplex weld personnel need to be informed that there are concerns for HIC, and with the typical 300 stainless series we have no concerns for HIC. With duplex we can use 250 - 300 F preheat to reduce the potential for HIC and also the pre-heat can help with weld fusion and reduce weld porosity.

WITH DUPLEX THERE SHOULD BE NO CONCERNS FOR HOT CRACKS: Due to the high ferrite content of the duplex aloys, these steels will have good hot cracking resistance.

WITH DUPLEX LESS CONCERN FOR DISTORTION: In contrast to stainless the higher ferrite ferrite duplex steels will have lower coefficient of expansion, therefore duplex steels should provide less weld distortion potential.

REALLY TAKE NOTE OF THE HAZ. When establishing the weld procedures always remember that duplex steels weld issues are frequently associated with the properties - problems that will occur in the weld's heat affected zone..

.